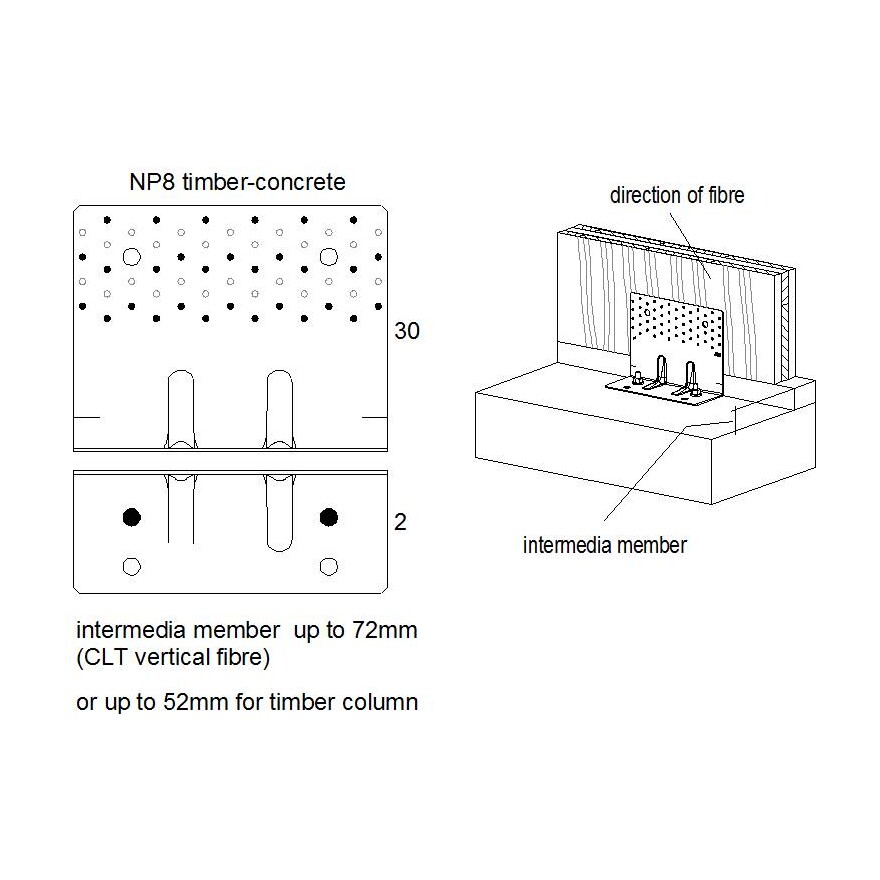

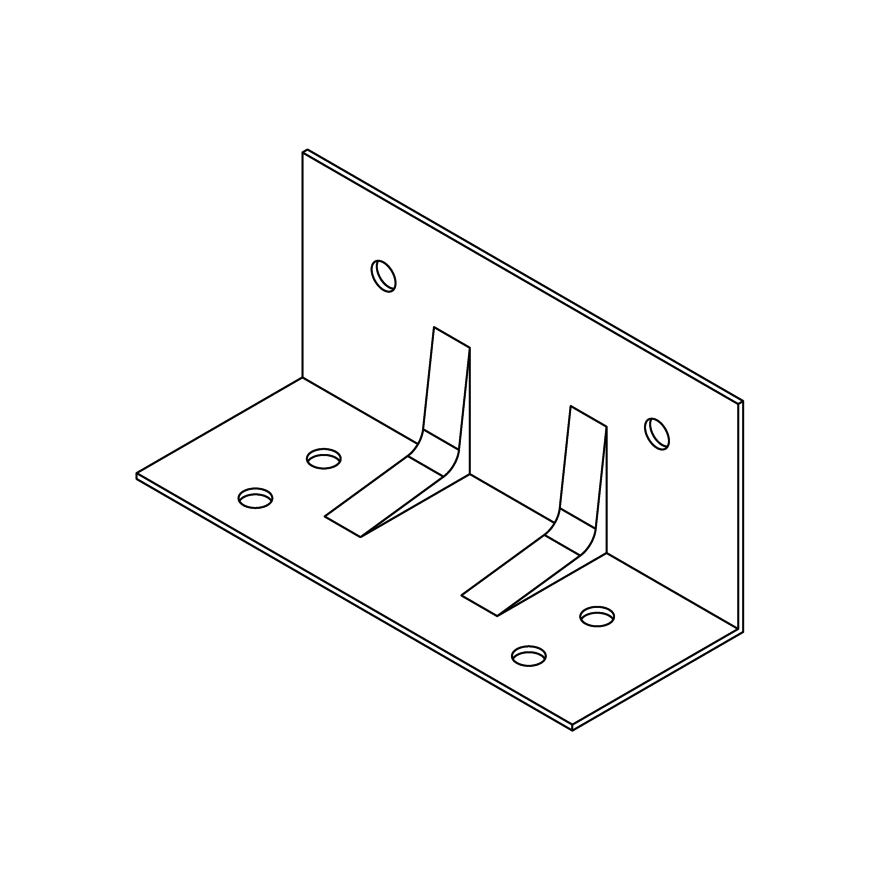

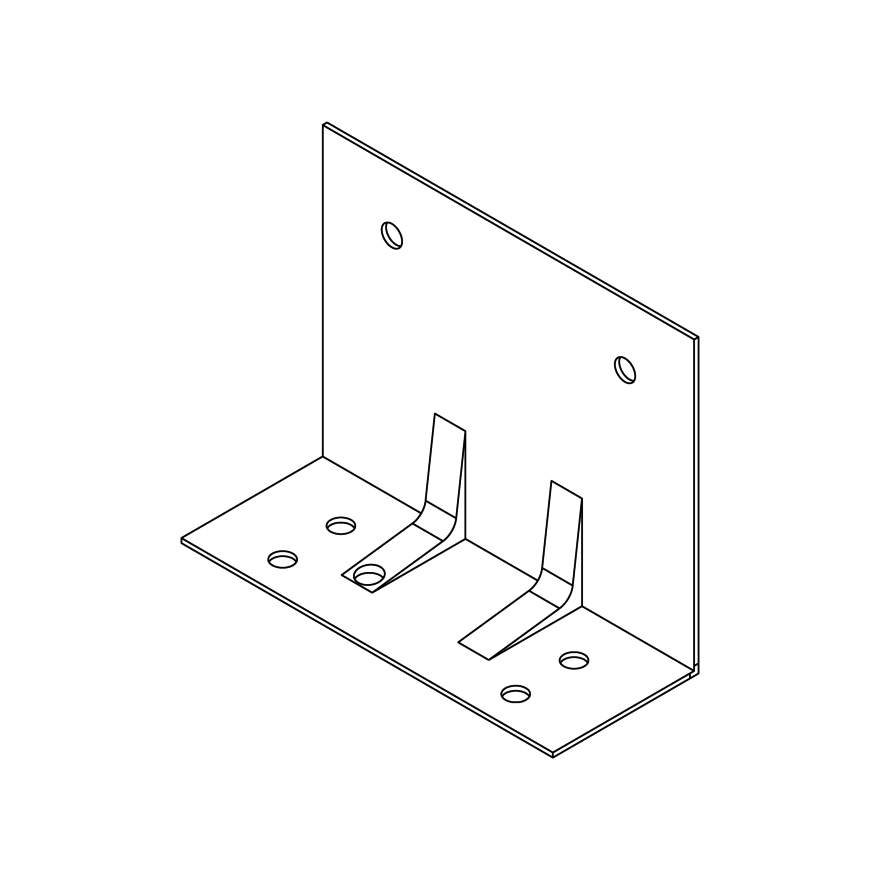

Vinkelbeslag till KL-trä

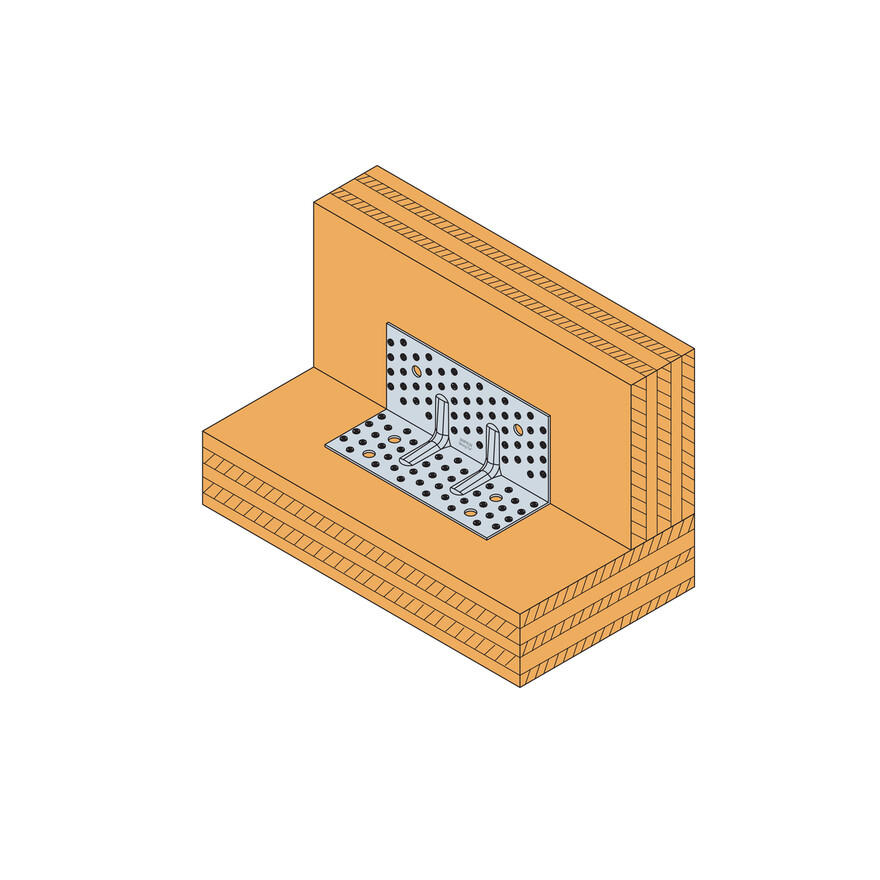

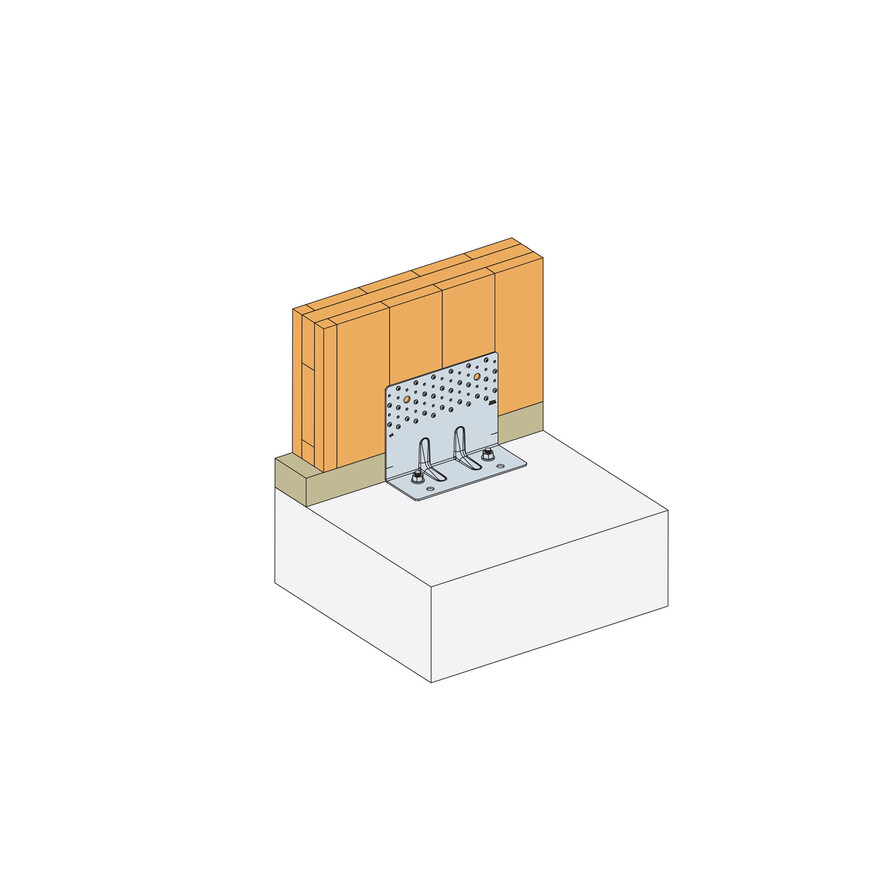

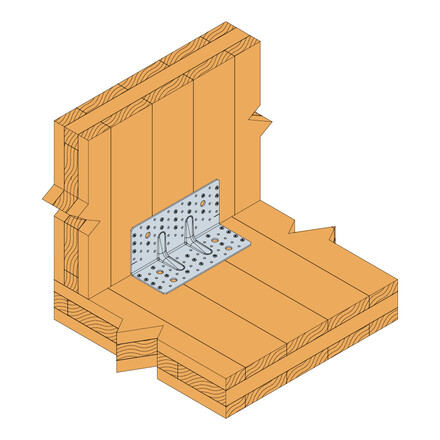

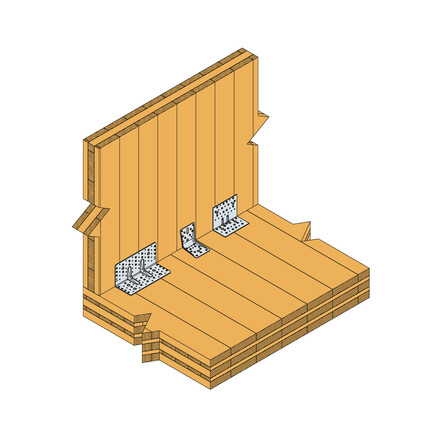

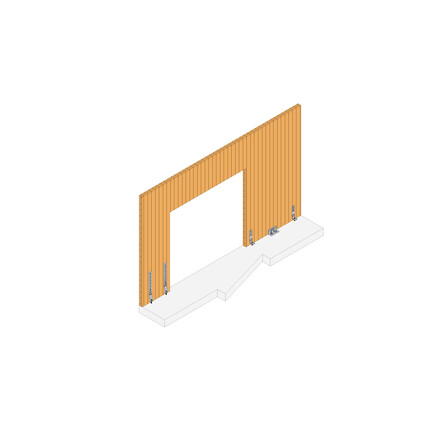

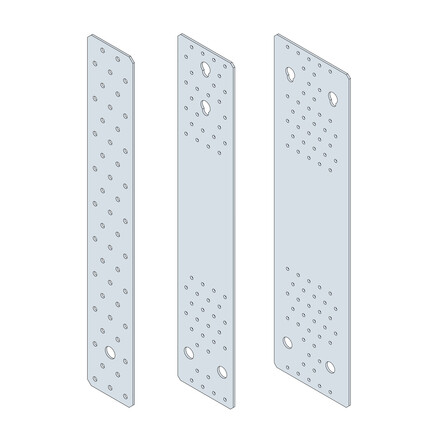

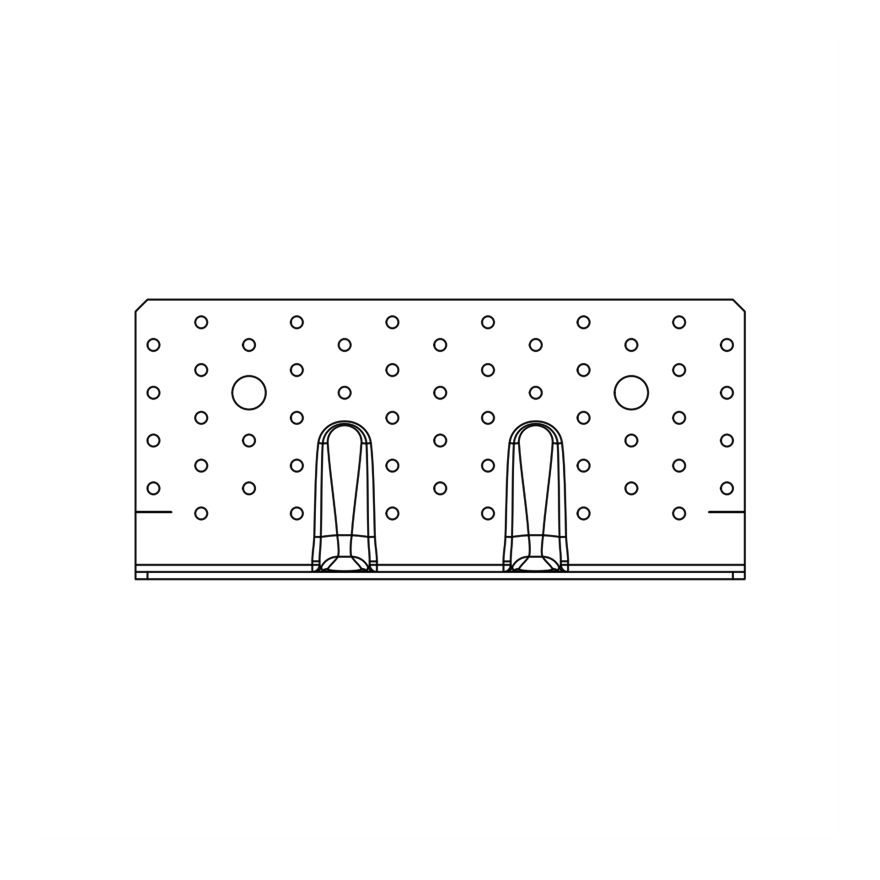

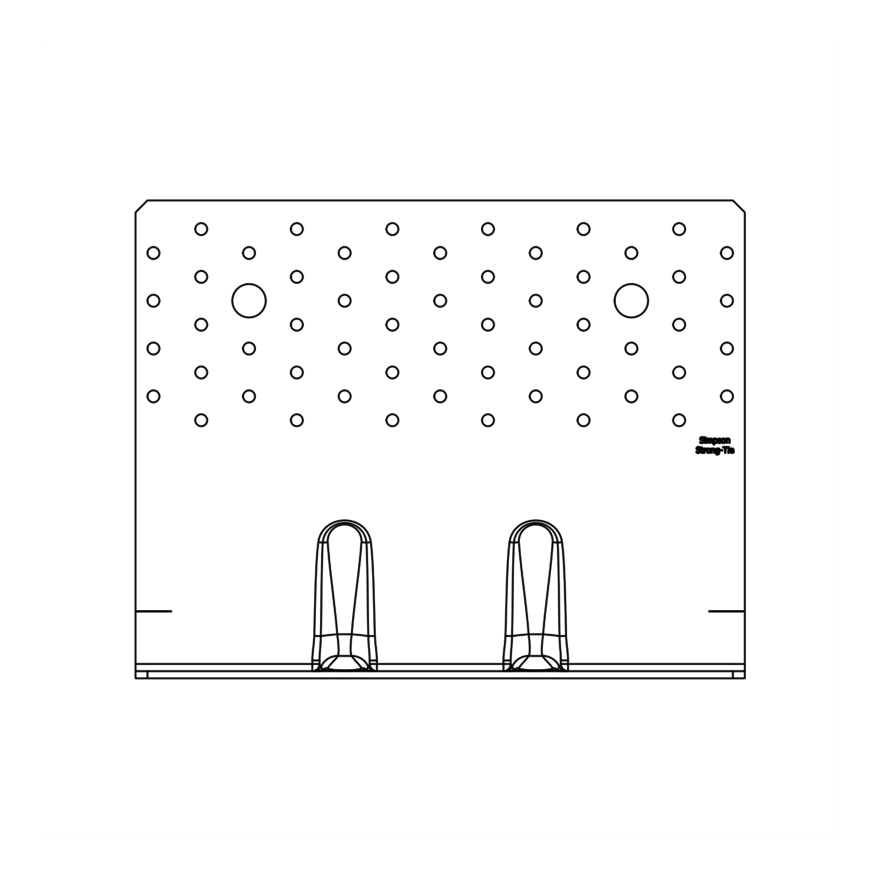

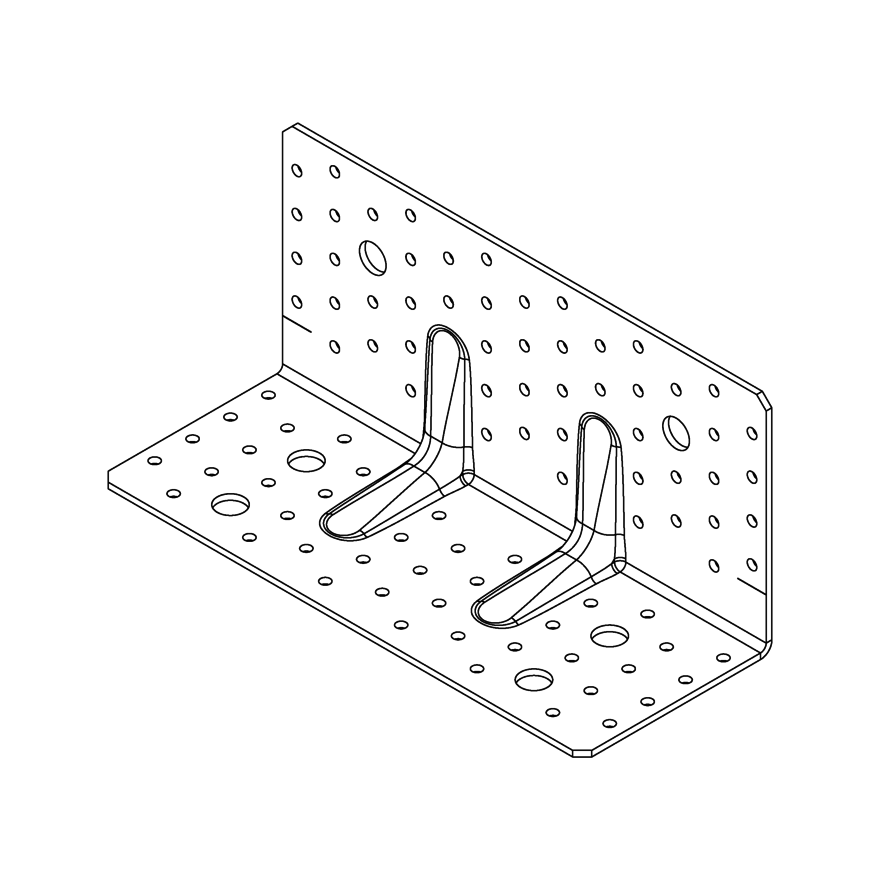

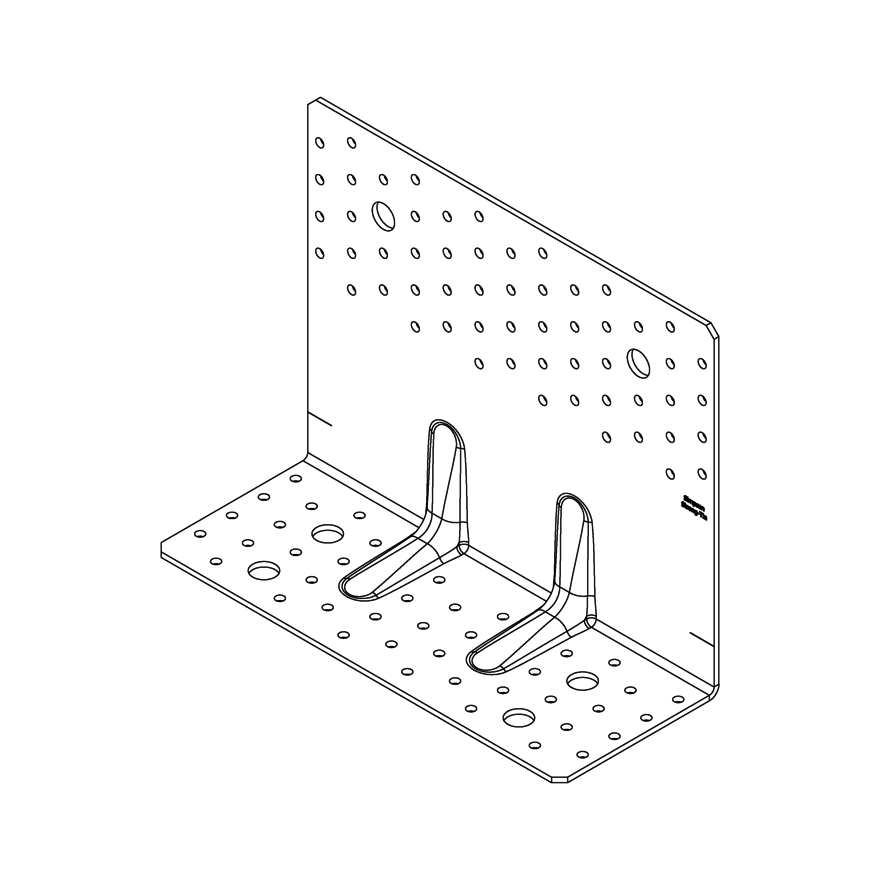

ABR255 används främst i KL-trä konstruktioner där det kan finnas stora horisontella tvärkrafter.

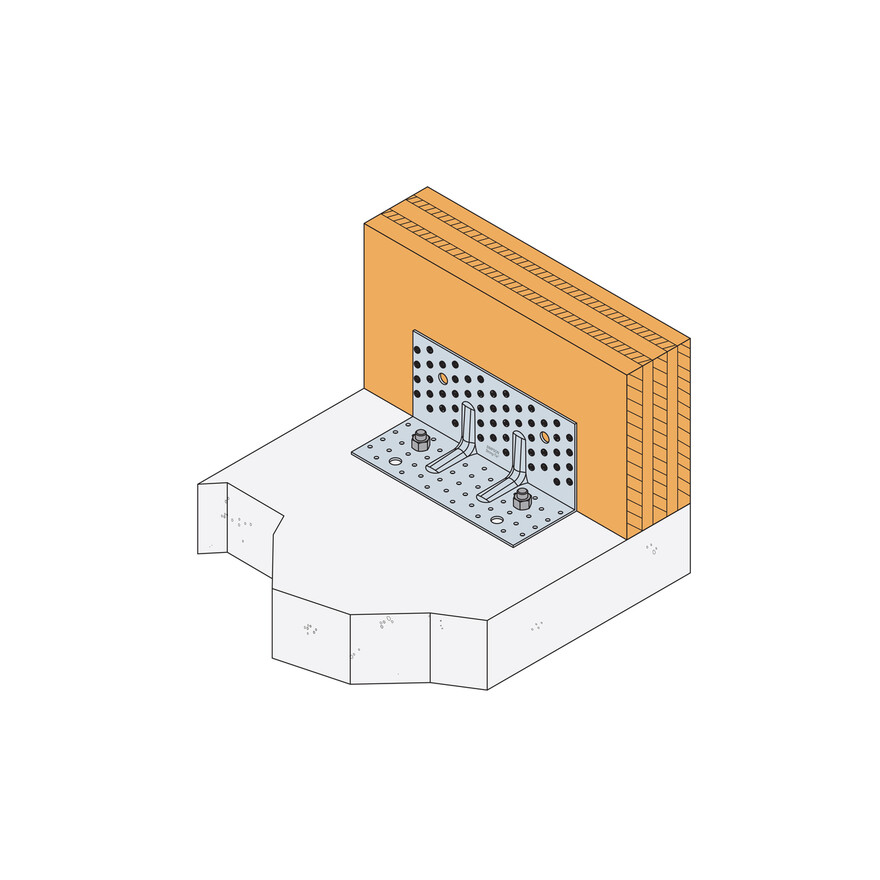

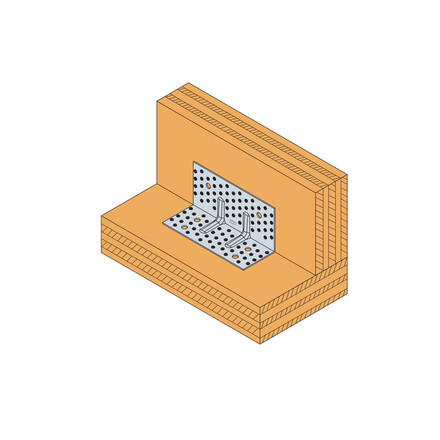

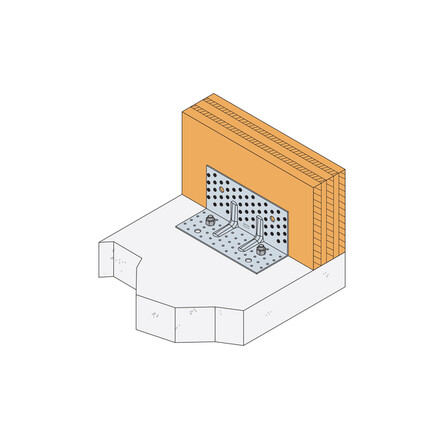

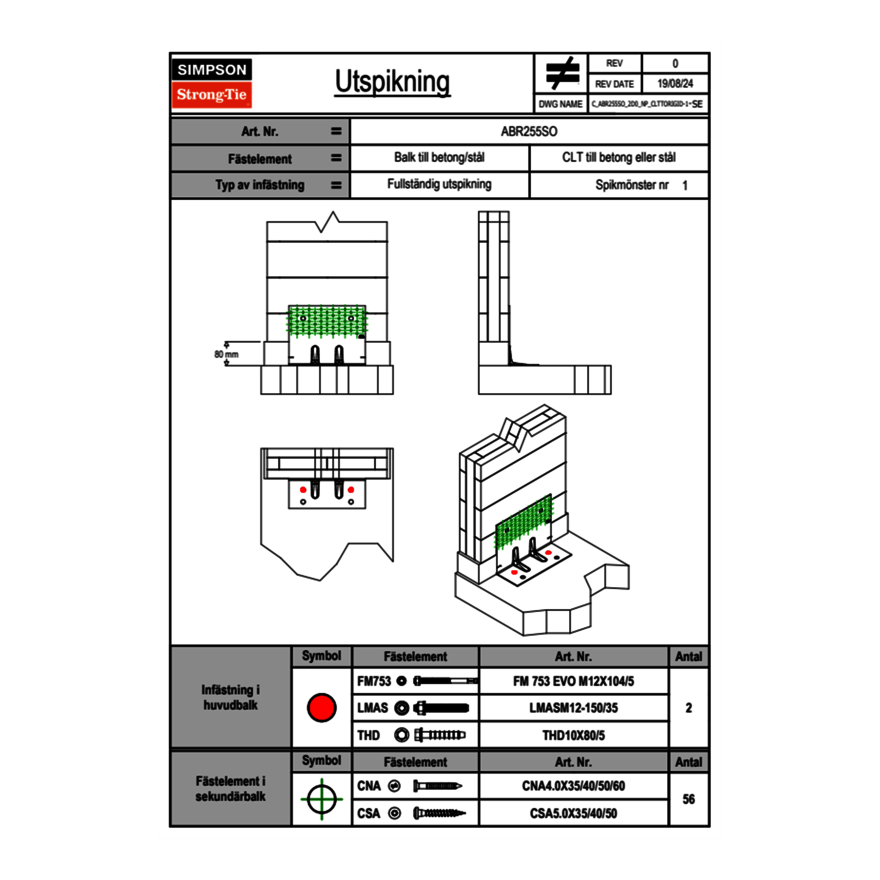

ABR255SO används i de situationer där det gjutits en syll/ram i betong som väggelementen monteras på.

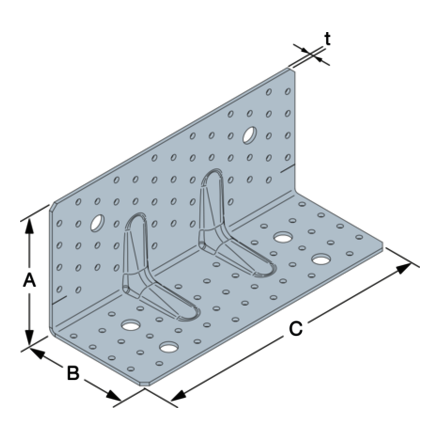

Produktinformation

Egenskaper

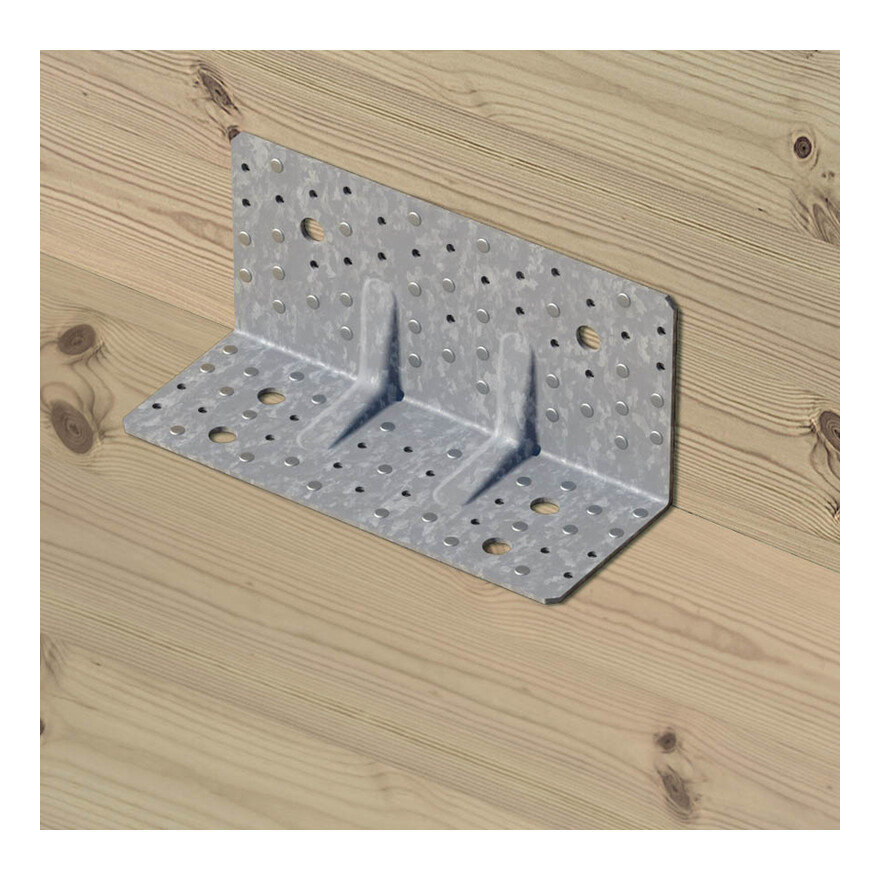

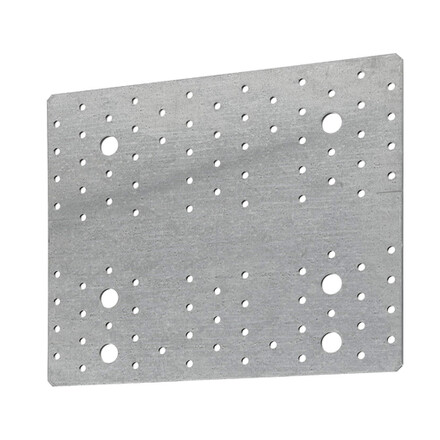

Material

- Stålkvalitet:

Galvaniserat stål S250GD + Z275 enligt EN 10346 - Korrosionsskydd:

275 g/m2 på båda sidorna när zinkbeläggningens tjocklek är cirka 20 μm

Fördelar

- Perfekt för CLT förbindelse

- Månsidig: Kan användas på trä- och betongunderlag

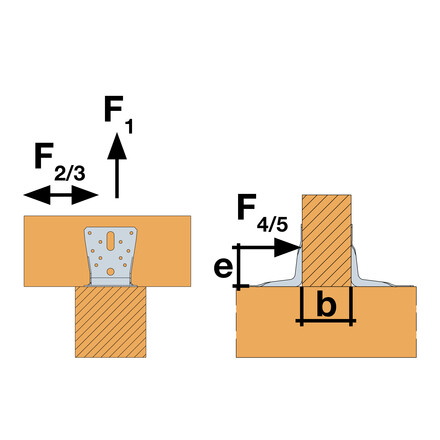

- Överlägsen prestanda för kraft i horisontella (F2/F3) och vertikala riktningar (F1)

Applikationer

Monteras på

- Bärande medlem: Massivt trä, limträ, betong, stål m.m.

- Stöttande medlem: Massivt trä, kompositträ, limträ.

Användningsområden

- CLT

Teknisk data

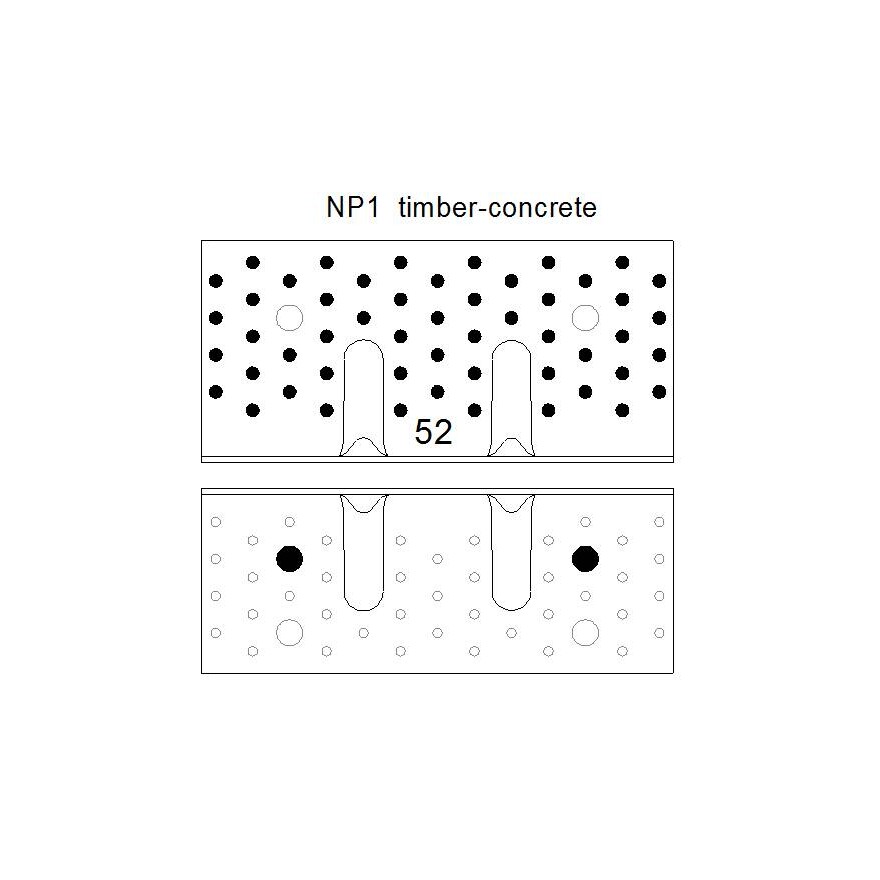

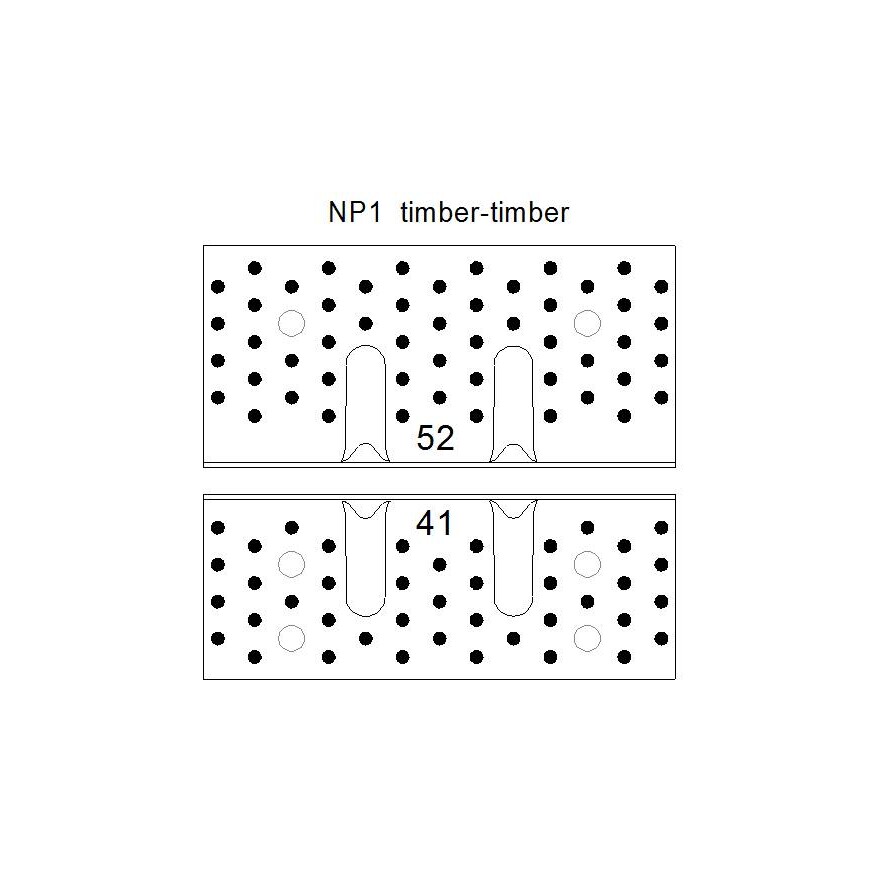

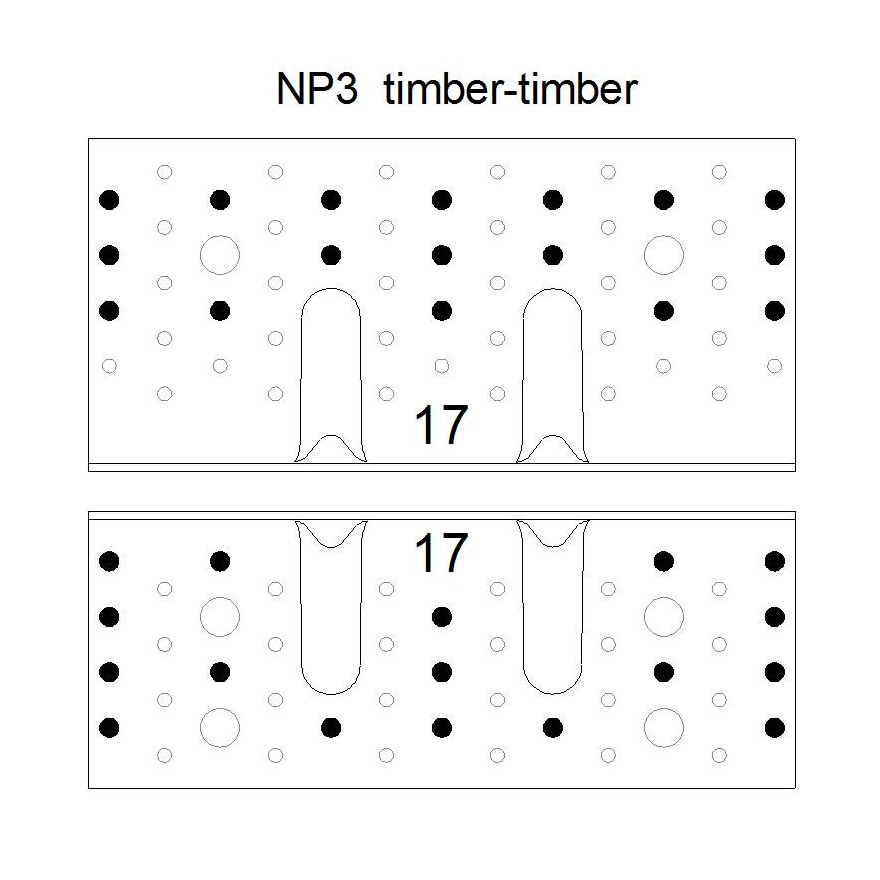

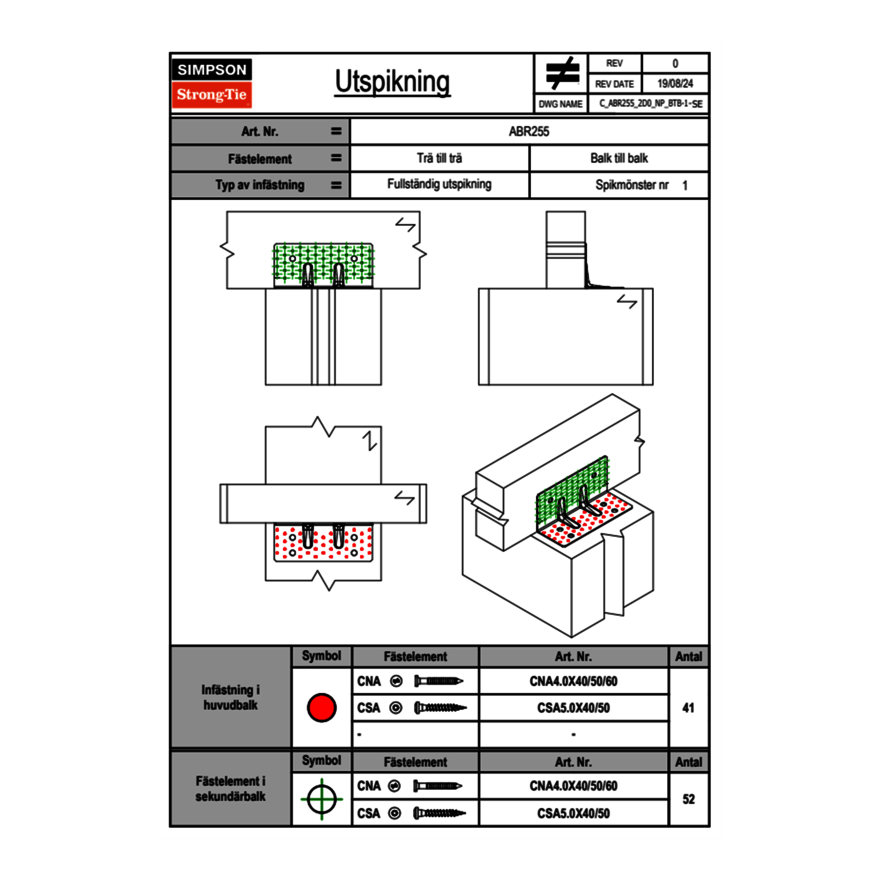

Karakteristisk bärförmåga - Balk-balk - 1 vinkelbeslag per fog - Fullständig utspikning - Nailing pattern 1

| Art. nr. | Karakteristisk bärförmåga - Balk-balk fogningar - Fullständig utspikning - Nailing pattern 1 | |||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Utspikning | Karakteristisk bärförmåga - 1 vinkelbeslag per fog [kN] | |||||||||||||||||

| Flik A | Flik B | R1.k | R2.k = R3.k | R4.k | R5.k | |||||||||||||

| - | - | CNA4.0x... | CNA4.0x... | CNA4.0x... | CNA4.0x... | |||||||||||||

| 35 | 40 | 50 | 60 | 35 | 40 | 50 | 60 | 35 | 40 | 50 | 60 | 35 | 40 | 50 | 60 | |||

| ABR255 | 52 | 41 | 14,1 / kmod^0,4 | 16 / kmod^0,4 | 19,5/ kmod^0,4 | 22,5 / kmod^0,4 | 33.5 | 37 | 45.9 | 50.5 | 12.5 | 14.9 | 18.2 | 21.1 | min (14.3 / kmod^0,4; 13.4/kmod) | min (15.7 / kmod^0,4; 13.4/kmod) | min (18.8 / kmod^0,4; 13.4/kmod) | 13.4/kmod |

Värdena gäller endast om elementen är föhindrade från att rotera.

-

| Art. nr. | - | |||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Utspikning | - [kN] | |||||||||||||||||

| Flik A | Flik B | R1.k | R2.k = R3.k | R4.k | R5.k | |||||||||||||

| - | - | CNA4.0x... | CNA4.0x... | CNA4.0x... | CNA4.0x... | |||||||||||||

| 35 | 40 | 50 | 60 | 35 | 40 | 50 | 60 | 35 | 40 | 50 | 60 | 35 | 40 | 50 | 60 | |||

| ABR255 | 52 | 41 | 14.7 | 16.7 | 20.3 | 23.5 | 33.5 | 37 | 45.9 | 50.5 | 12.5 | 14.9 | 18.2 | 21.1 | 14.8 | 14.8 | 14.8 | 14.8 |

The published characteristic capacity is based on short term load duration and service class 2 according to EC5 (EN 1995) – kmod = 0.9. For other load duration and service class, please refer to the ETA to get more accurate capacities.

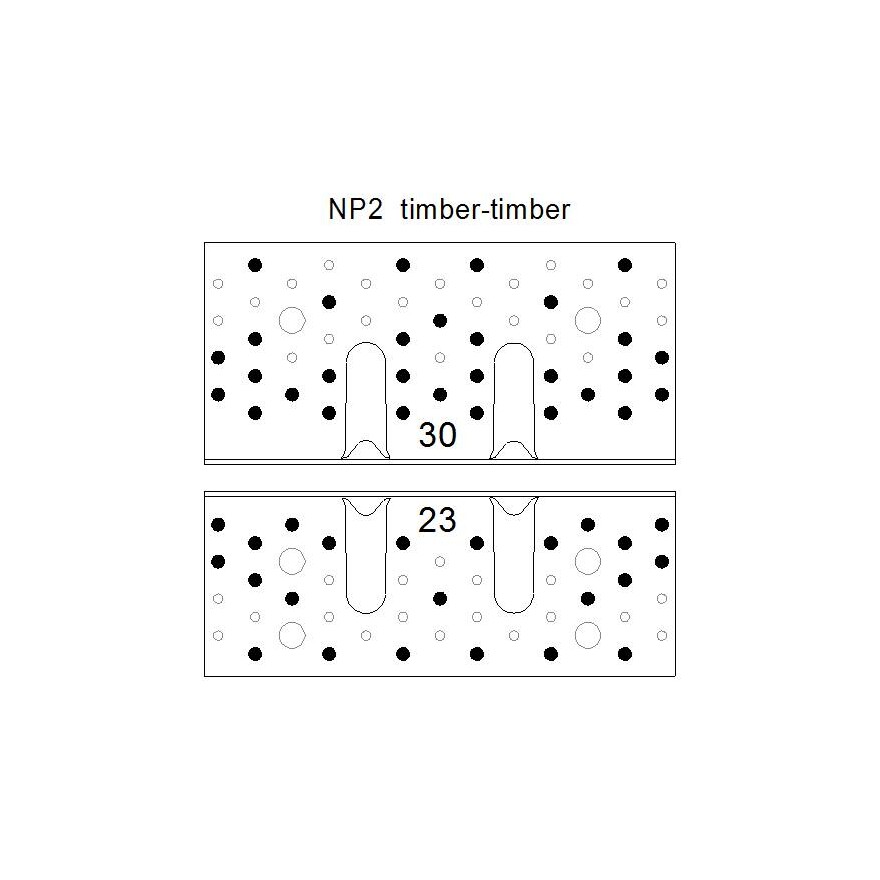

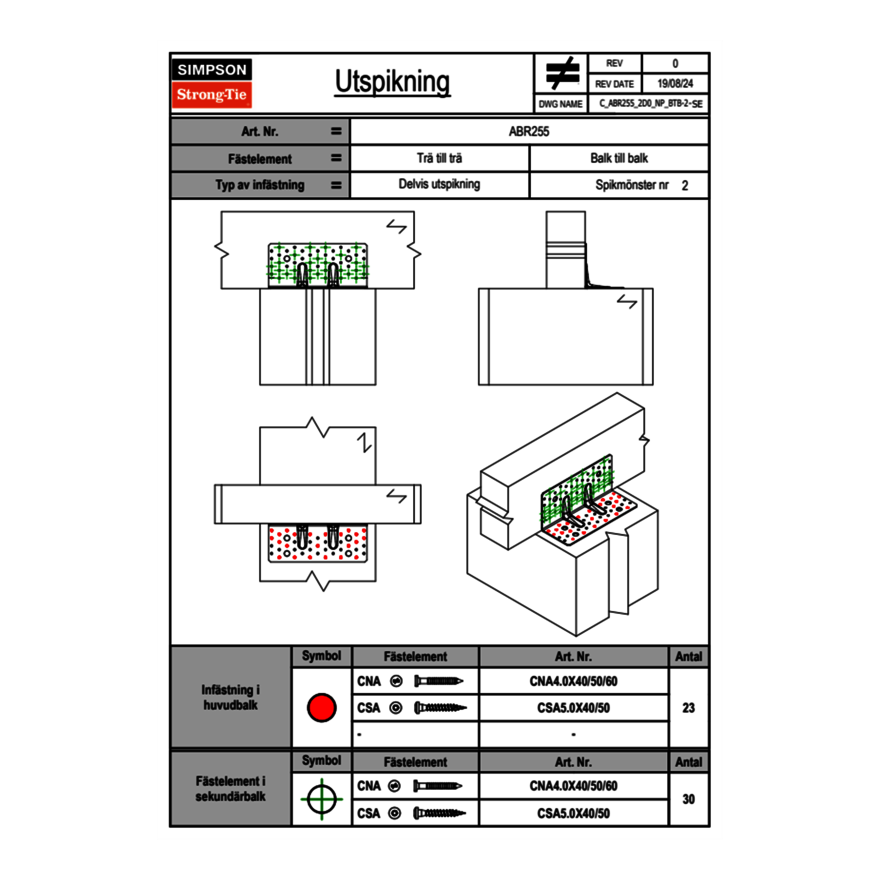

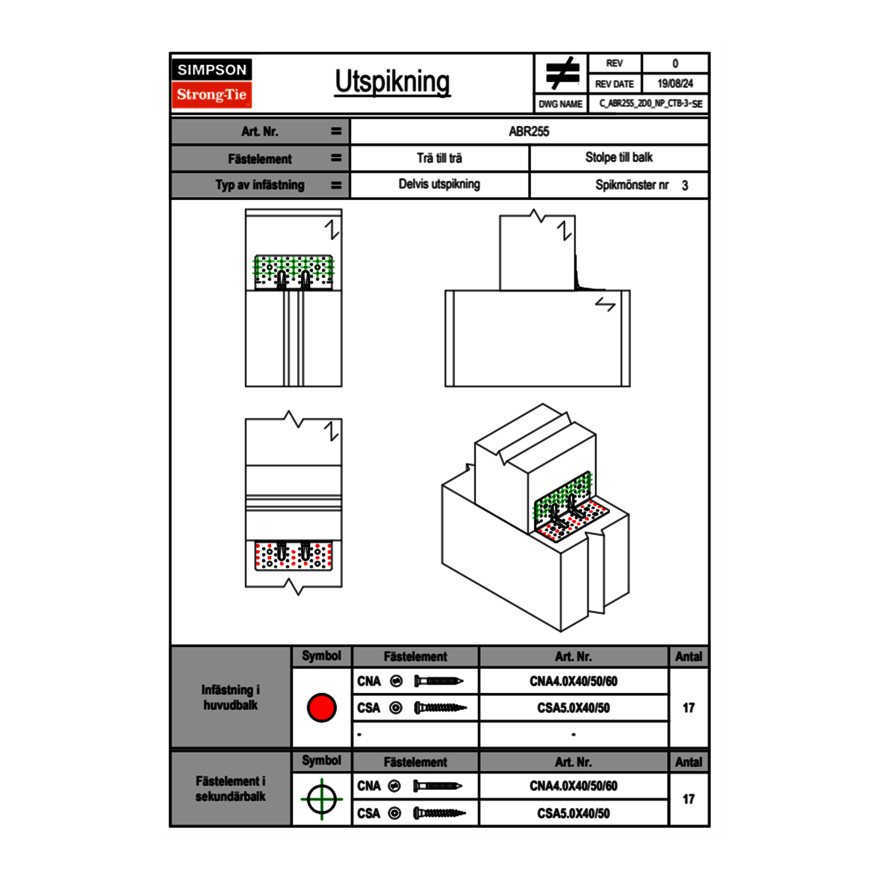

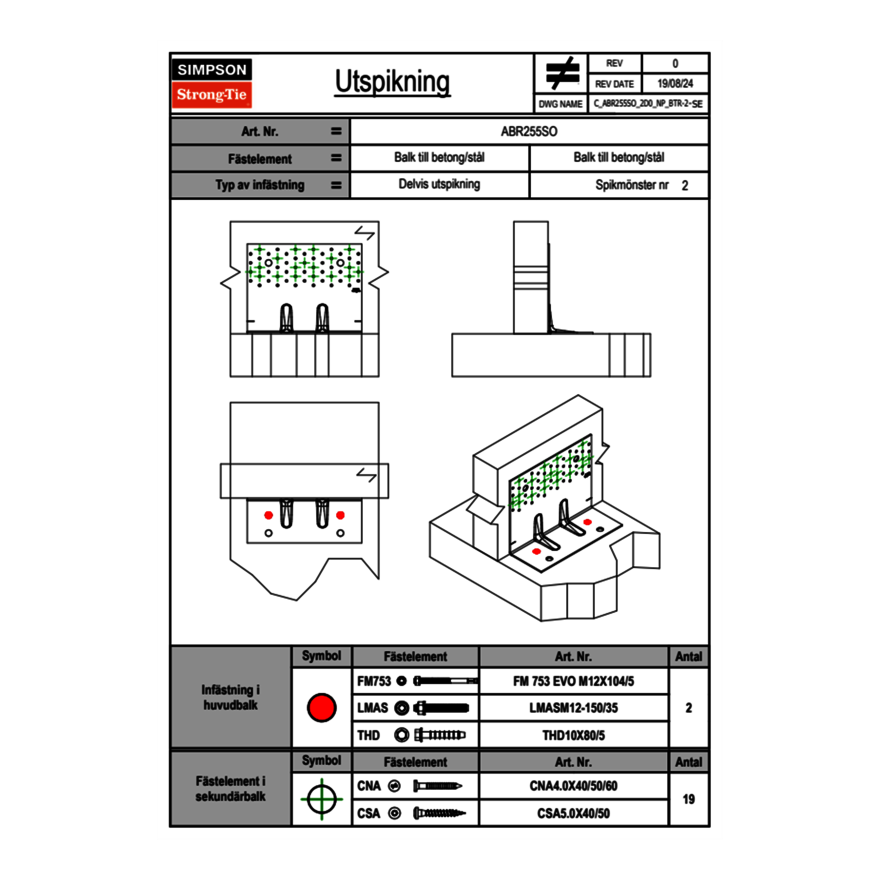

Karakteristisk bärförmåga - Balk-balk - 1 vinkelbeslag per fog - Delvis utspikning - Nailing pattern 2

| Art. nr. | Karakteristisk bärförmåga - Balk-balk fogningar - Delvis utspikning - Nailing pattern 2 | |||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Utspikning | Karakteristisk bärförmåga - 1 vinkelbeslag per fog [kN] | |||||||||||||||||

| Flik A | Flik B | R1.k | R2.k = R3.k | R4.k | R5.k | |||||||||||||

| - | - | CNA4.0x... | CNA4.0x... | CNA4.0x... | CNA4.0x... | |||||||||||||

| 35 | 40 | 50 | 60 | 35 | 40 | 50 | 60 | 35 | 40 | 50 | 60 | 35 | 40 | 50 | 60 | |||

| ABR255 | 30 | 23 | 12,2 / kmod^0,4 | 13,7 / kmod^0,4 | 16,5 / kmod^0,4 | 19,5 / kmod^0,4 | 27.4 | 30.5 | 38 | 42.1 | 12.2 | 13.8 | 16.9 | 19.5 | min (11.5 ; 13.9/kmod) | min (13.6 ; 13.9/kmod) | min (18 ; 13.9/kmod) | min (22 ; 13.9/kmod) |

Värdena gäller endast om elementet är förhindrat från att rotera.

-

| Art. nr. | - | |||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Utspikning | - [kN] | |||||||||||||||||

| Flik A | Flik B | R1.k | R2.k = R3.k | R4.k | R5.k | |||||||||||||

| - | - | CNA4.0x... | CNA4.0x... | CNA4.0x... | CNA4.0x... | |||||||||||||

| 35 | 40 | 50 | 60 | 35 | 40 | 50 | 60 | 35 | 40 | 50 | 60 | 35 | 40 | 50 | 60 | |||

| ABR255 | 30 | 23 | 12.7 | 14.3 | 17.2 | 20.3 | 27.4 | 30.5 | 38 | 42.1 | 12.2 | 13.8 | 16.9 | 19.5 | 11.5 | 13.6 | 15.4 | 15.4 |

The published characteristic capacity is based on short term load duration and service class 2 according to EC5 (EN 1995) – kmod = 0.9. For other load duration and service class, please refer to the ETA to get more accurate capacities.

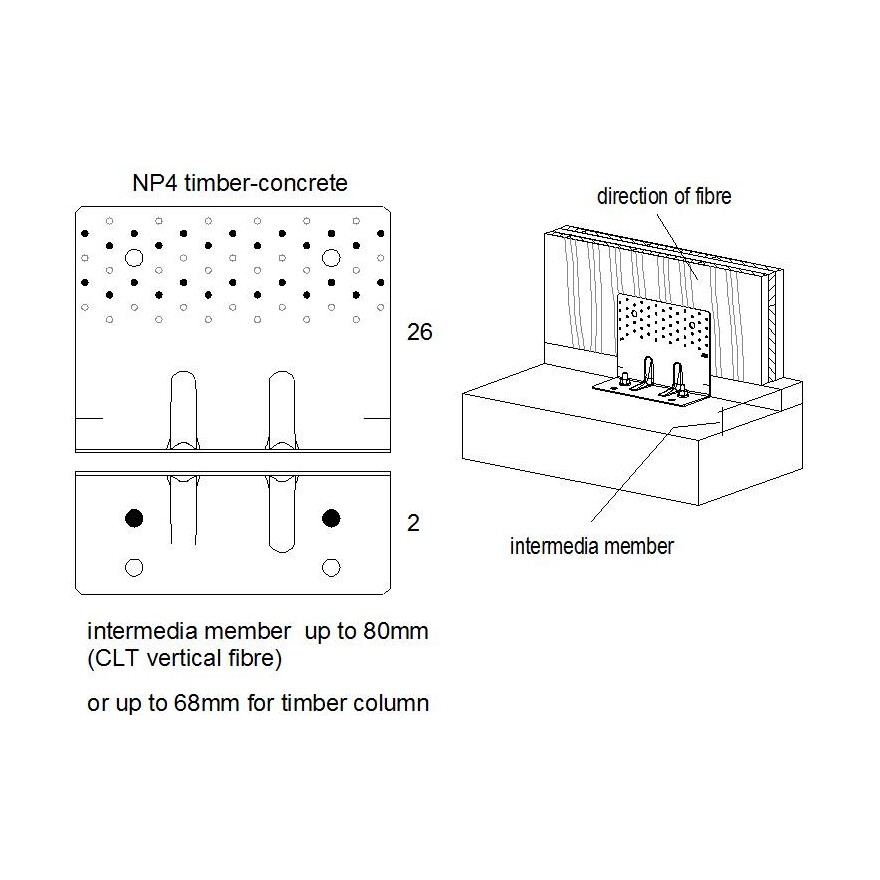

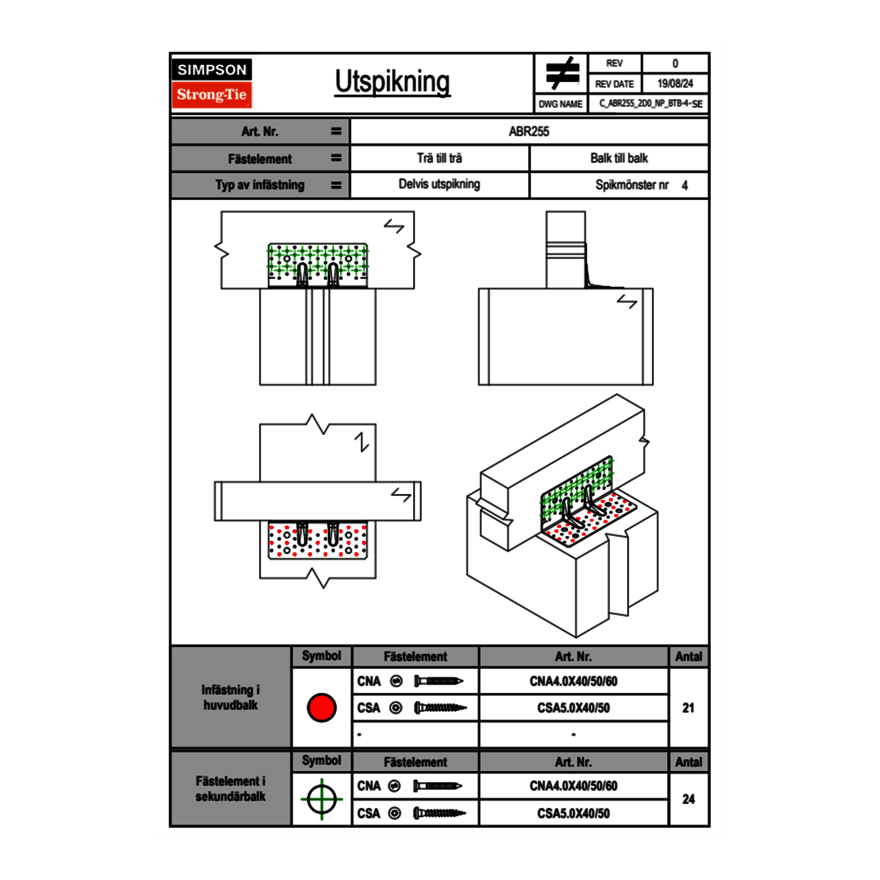

Karakteristisk bärförmåga - Balk-balk - 1 vinkelbeslag per fog - Delvis utspikning - Nailing pattern 4

| Art. nr. | Karakteristisk bärförmåga - Balk-balk fogningar - Delvis utspikning - Nailing pattern 4 | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Utspikning | Karakteristisk bärförmåga - 1 vinkelbeslag per fog [kN] | |||||||||

| Flik A | Flik B | Uppåtriktad lastbärförmåga | Skjuvhållfasthet [F2=F3] | R4.k | R5.k | |||||

| - | - | CNA4,0x... | CNA4.0x... | CNA4.0x... | CNA4.0x... | |||||

| 50 | 60 | 50 | 60 | 50 | 60 | 50 | 60 | |||

| ABR255 | 24 | 21 | 15,6/kmod^0,4 | 18,1/kmod^0,4 | 28.6 | 31.4 | 15.9 | 18.3 | 10.8/kmod^0.3 | min (12.7/kmod^0,3 ; 12.8 / kmod) |

The value in the table above can be used if the panel can't rotate.

Nailing pattern 4 has been specifically developed for CLT application. It can be used for applications with other timber based materials provided that the materials comply with the spacing and distances of fasteners in CLT.

Förenklade karakteristiska kapaciteter – Trä mot trä – 1 vinkelbeslag – Partiell spikning – Spikmönster 4

| Art. nr. | Förenklade produktkapaciteter – Trä på trä – Delvis spikning – Spikmönster 4 | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Fasteners | Simplified characteristic capacities - Timber C24 - 1 angle bracket per connection [kN] | |||||||||

| Flange A | Flange B | R1.k | R2.k = R3.k | R4.k | R5.k | |||||

| Qty | Qty | CNA4.0x50 | CNA4.0x60 | CNA4.0x50 | CNA4.0x60 | CNA4.0x50 | CNA4.0x60 | CNA4.0x50 | CNA4.0x60 | |

| ABR255 | 24 | 21 | 16.2 | 18.8 | 28.6 | 31.4 | 15.9 | 18.3 | 11.1 | 16.7 |

The published characteristic capacity is based on short term load duration and service class 2 according to EC5 (EN 1995) – kmod = 0.9. For other load duration and service class, please refer to the ETA to get more accurate capacities.

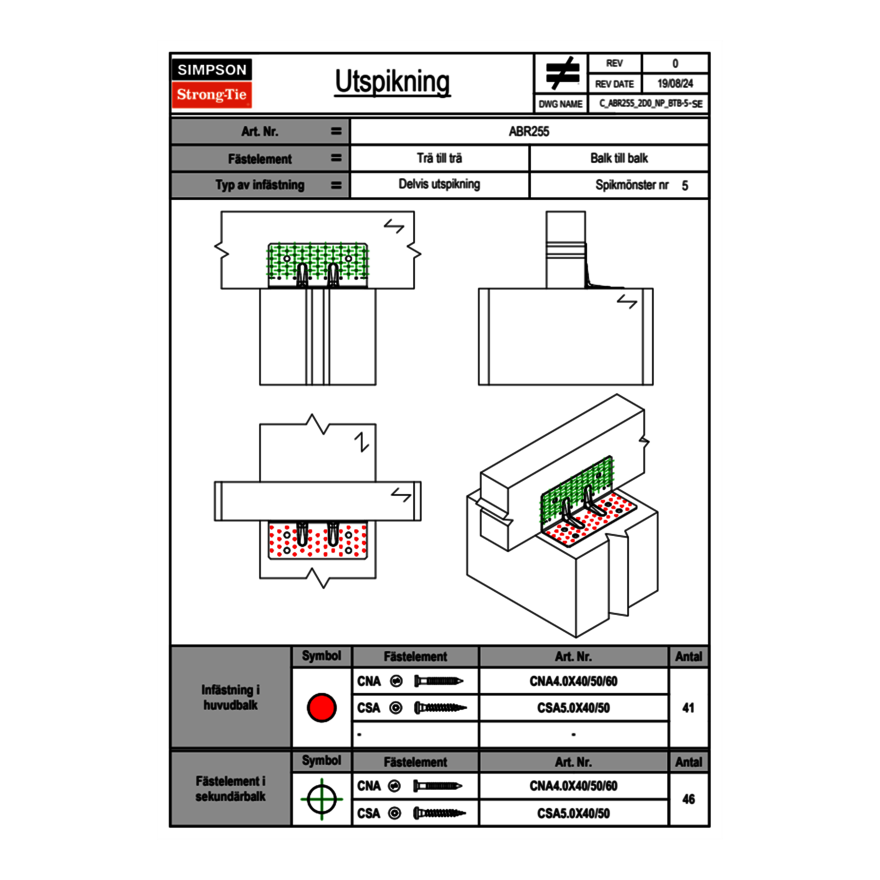

Karakteristisk bärförmåga - Balk-balk - 1 vinkelbeslag per fog - Delvis utspikning - Nailing pattern 5

| Art. nr. | Karakteristisk bärförmåga - Balk-balk fogningar - Delvis utspikning - Nailing pattern 5 | |||

|---|---|---|---|---|

| Utspikning | Karakteristisk bärförmåga - 1 vinkelbeslag per fog [kN] | |||

| Flik A | Flik B | Uppåtriktad lastbärförmåga | Skjuvhållfasthet [F2=F3] | |

| - | - | CSA 5,0x50 | CSA 5,0x50 | |

| ABR255 | 46 | 41 | 23,6 / kmod | 51.7 |

The value in the table above can be used if the panel can't rotate.

Nailing pattern 5 has been specifically developed for CLT application. It can be used for applications with other timber based materials provided that the materials comply with the spacing and distances of fasteners in CLT.

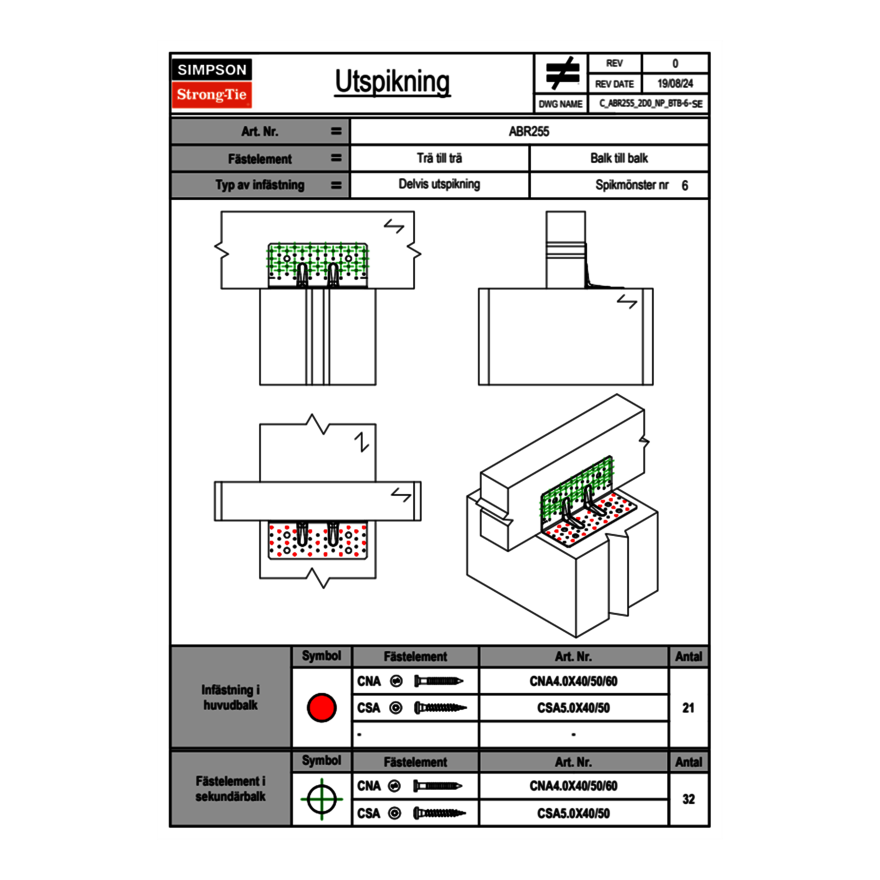

Karakteristisk bärförmåga - Balk-balk - 1 vinkelbeslag per fog - Delvis utspikning - Nailing pattern 6

| Art. nr. | Karakteristisk bärförmåga - Balk-balk fogningar - Delvis utspikning - Nailing pattern 6 | |||||

|---|---|---|---|---|---|---|

| Utspikning | Karakteristisk bärförmåga - 1 vinkelbeslag per fog [kN] | |||||

| Flik A | Flik B | R1.k | R2,k = R3,k | |||

| - | - | CNA4.0x50 | CNA4.0x60 | CNA4.0x50 | CNA4.0x60 | |

| ABR255 | 32 | 21 | - | - | 36.1 | 39.2 |

The value in the table above can be used if the panel can't rotate.

Nailing pattern 6 has been specifically developed for CLT application. It can be used for applications with other timber based materials provided that the materials comply with the spacing and distances of fasteners in CLT.

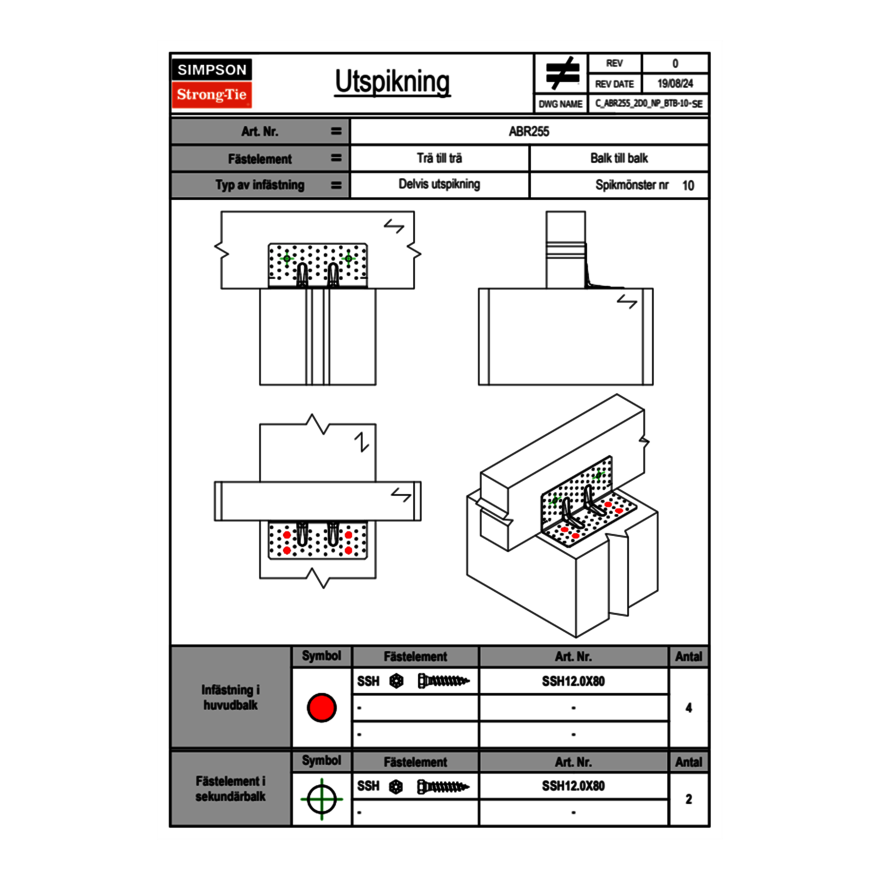

Karakteristisk bärförmåga - CLT Balk-CLT Balk - Ø12 Betongskruvar - 1 vinkelbeslag per fog

| Art. nr. | Karakteristisk bärförmåga - CLT Balk-CLT Balk - Ø12 Betongskruvar - 1 vinkelbeslag per fog | |||||

|---|---|---|---|---|---|---|

| Utspikning | Characteristic capacities - Timber C24 - 1 angle bracket per connection [kN] | |||||

| Flik A | Flik B | R1.k | R2.k = R3.k | |||

| Antal | Typ | Antal | Typ | SSH12x80 | SSH12x80 | |

| ABR255 | 2 | SSH | 4 | SSH | 13.4 | 16.6 |

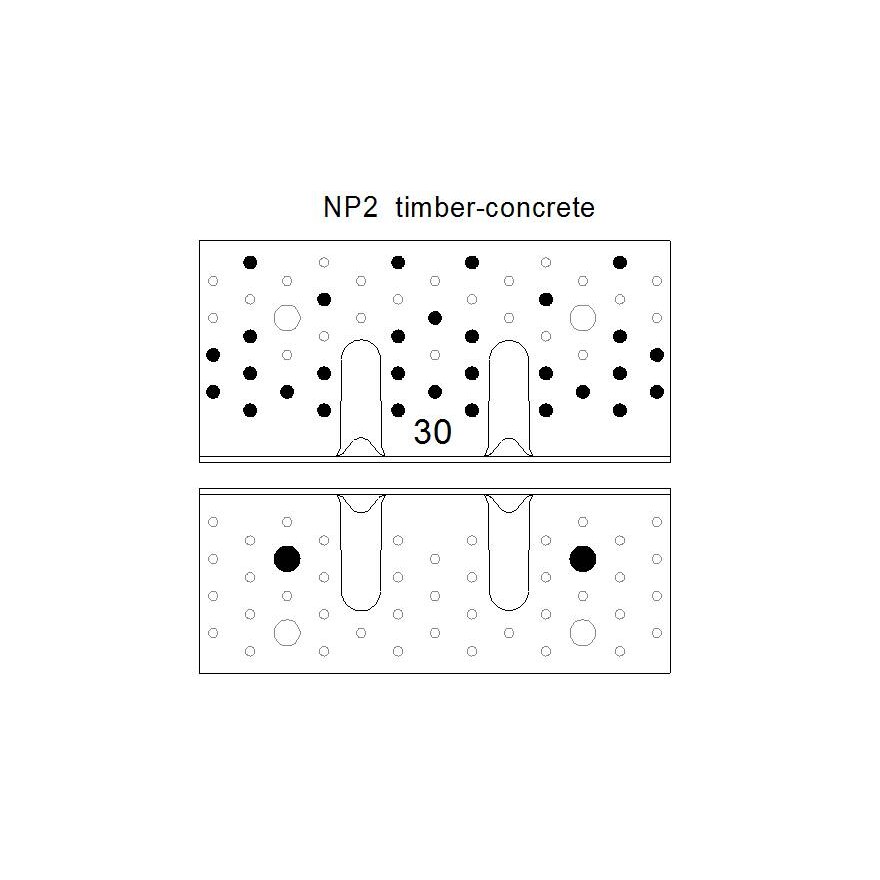

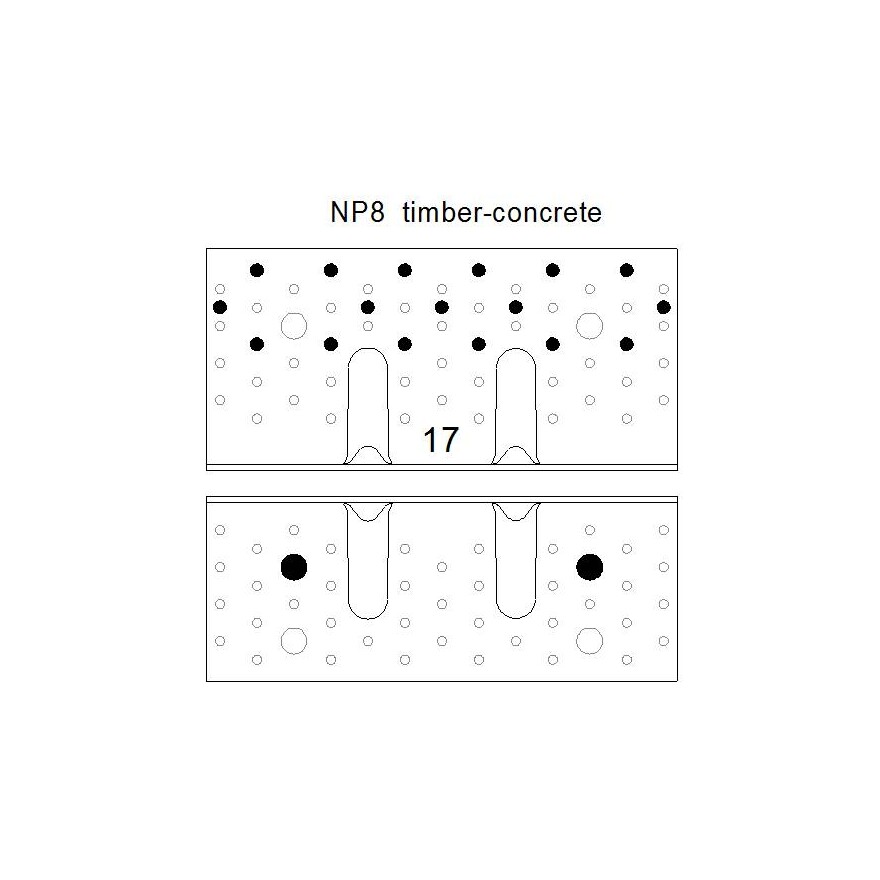

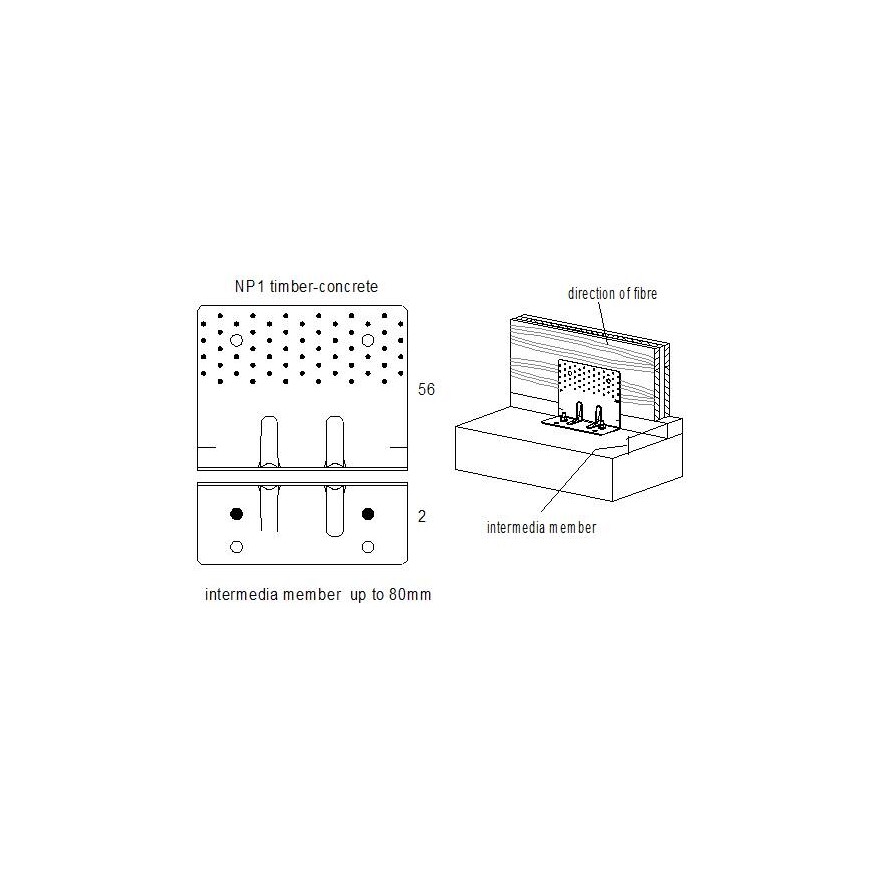

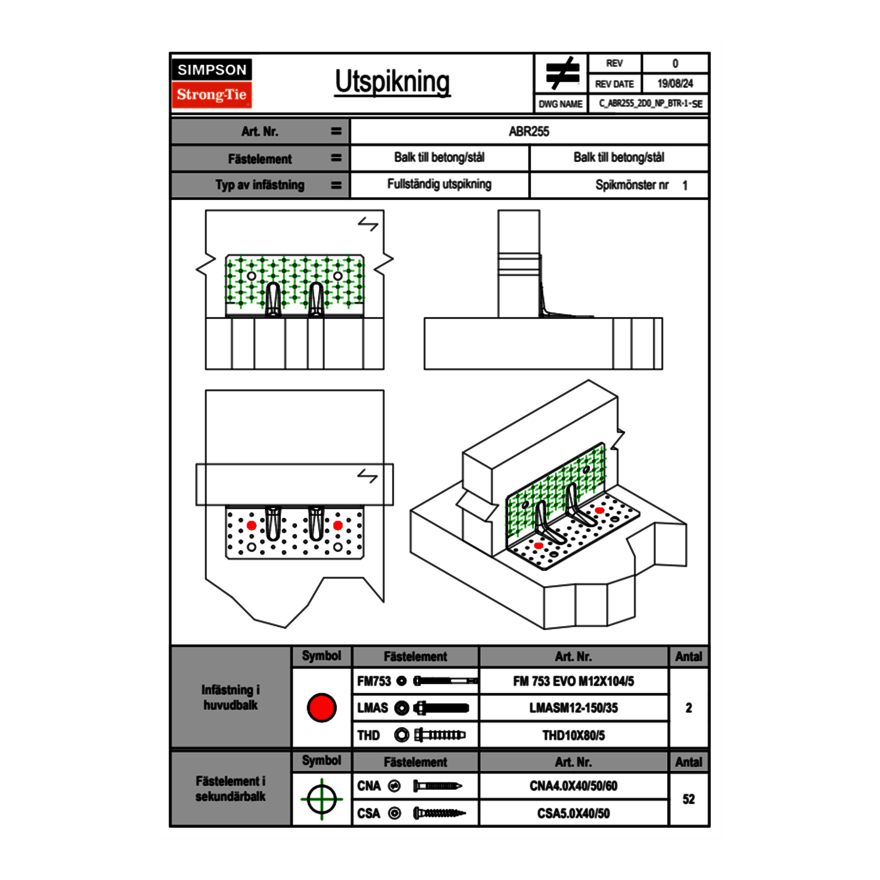

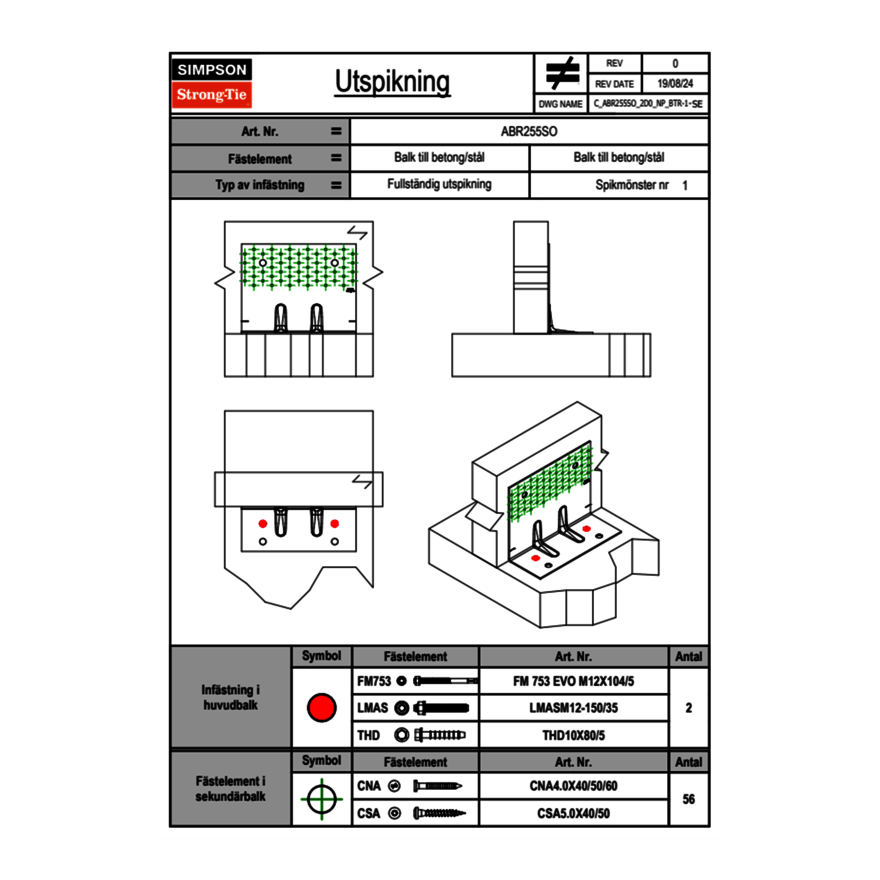

Karakteristisk bärförmåga - Balk på betong - 1 vinkelbeslag per fog - Fullständig utspikning - Nailing pattern 1

| Art. nr. | Karakteristisk bärförmåga - Balk-betong fogningar - Fullständig utspikning | |||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Utspikning | Karakteristisk bärförmåga - 1 vinkelbeslag per fog [kN] | |||||||||||||||||||||

| Flik A | Flik B | R1.k | R2.k = R3.k | R4.k | R5.k | |||||||||||||||||

| - | Typ | - | Typ | CNA4.0x... | CNA4.0x... | CNA4.0x... | CNA4.0x... | |||||||||||||||

| 35-50-60 | 35 | 40 | 50 | 60 | 35 | 40 | 50 | 60 | 35-50-60 | 35 | 40 | 50 | 60 | 35 | 40 | 50 | 60 | |||||

| ABR255 | 52 | CNA | 2 | Ø12 | 22 / kmod | 22 / kmod | 22 / kmod | 22 / kmod | 22 / kmod | 33 | 36 | min (45,3 ; 42,9/kmod) | min (49,2 ; 42,9/kmod) | 18.3 / kmod^0,7 | 18.3/kmod^0,7 | 18.3/kmod^0,7 | 18.3/kmod^0,7 | 18.3/kmod^0,7 | min (17.1/kmod^0.25 ; 17.7/kmod) | min (19.5/kmod^0.25 ; 17.7/kmod) | min (23.5/kmod^0.25 ; 17.7/kmod) | min (27.3/kmod^0.25 ; 17.7/kmod) |

| ABR255SO | 56 | CNA | 2 | Ø12 | 22,9 / kmod | 22,9/kmod | 22,9/kmod | 22,9/kmod | 22,9/kmod | 29.2 | 32.5 | 38.6 | - | 18,6 / kmod^0,66 | 18,6/kmod^0,66 | 18,6/kmod^0,66 | 18,6/kmod^0,66 | 18,6/kmod^0,66 | 5,05/kmod | 5,05/kmod | 5,05/kmod | 5,05/kmod |

Värdena gäller endast om elementen är förhindrare från att rotera.

-

| Art. nr. | - | |||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Utspikning | - [kN] | |||||||||||||||||||

| Flik A | Flik B | R1.k | R2.k = R3.k | R4.k | R5.k | |||||||||||||||

| - | Typ | - | Typ | CNA4.0x... | CNA4.0x... | CNA4.0x... | CNA4.0x... | |||||||||||||

| 35 | 40 | 50 | 60 | 35 | 40 | 50 | 60 | 35 | 40 | 50 | 60 | 35 | 40 | 50 | 60 | |||||

| ABR255 | 52 | CNA | 2 | Ø12 | 24.4 | 24.4 | 24.4 | 24.4 | 25.1 | 29.2 | 45.3 | 49.2 | 19.7 | 19.7 | 19.7 | 19.7 | 17.5 | 19.6 | 19.6 | 19.6 |

| ABR255SO | 56 | CNA | 2 | Ø12 | 20.8 | 20.8 | 20.8 | 20.8 | 29.2 | 32.5 | 38.6 | - | 17.1 | 17.1 | 17.1 | 17.1 | 4.6 | 4.6 | 4.6 | 4.6 |

The published characteristic capacity is based on short term load duration and service class 2 according to EC5 (EN 1995) – kmod = 0.9. For other load duration and service class, please refer to the ETA to get more accurate capacities.

The bolt design resistance requirement R#,d is determined from (bolt factor x connection design load F#,d) for the required load direction and fastener. Refer to the Simpson Strong-Tie anchor product range for suitable anchors. Typical anchor solutions are BOAXII, SET-XP, WA, AT-HP, depending on the concrete type, spacing and edge distances.

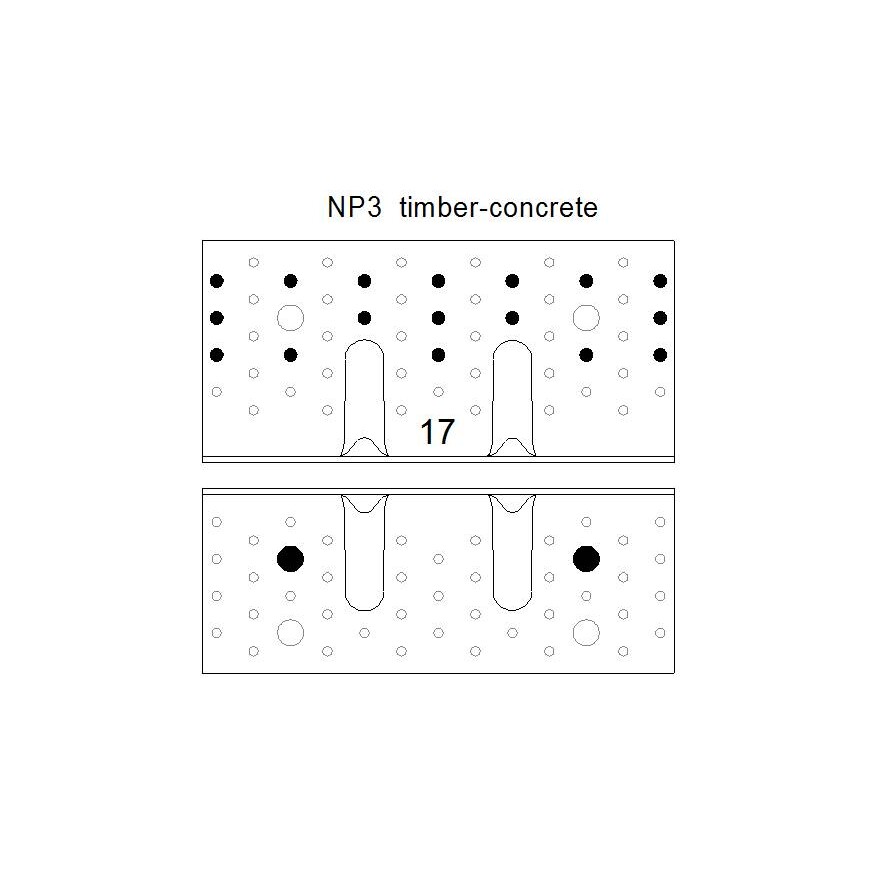

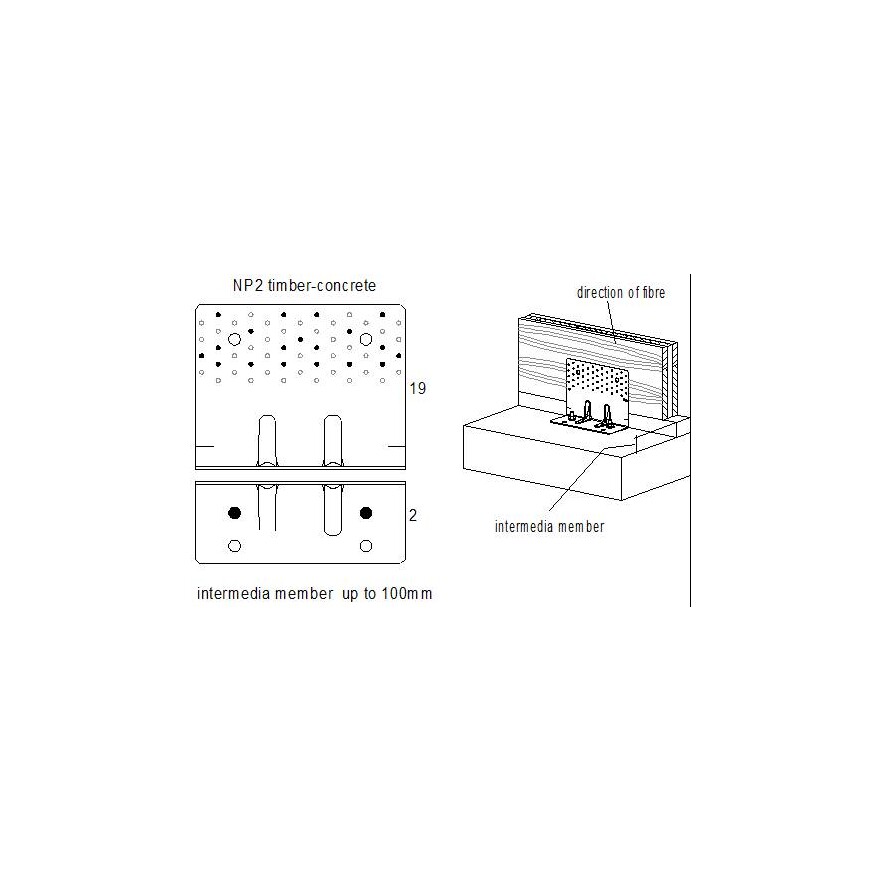

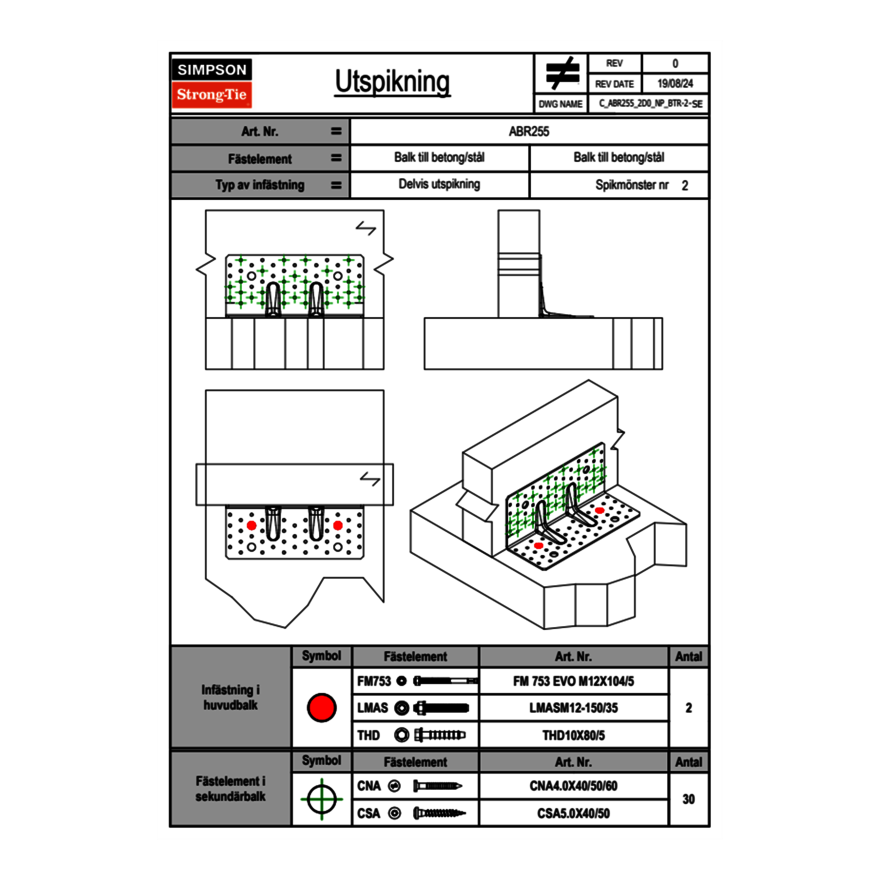

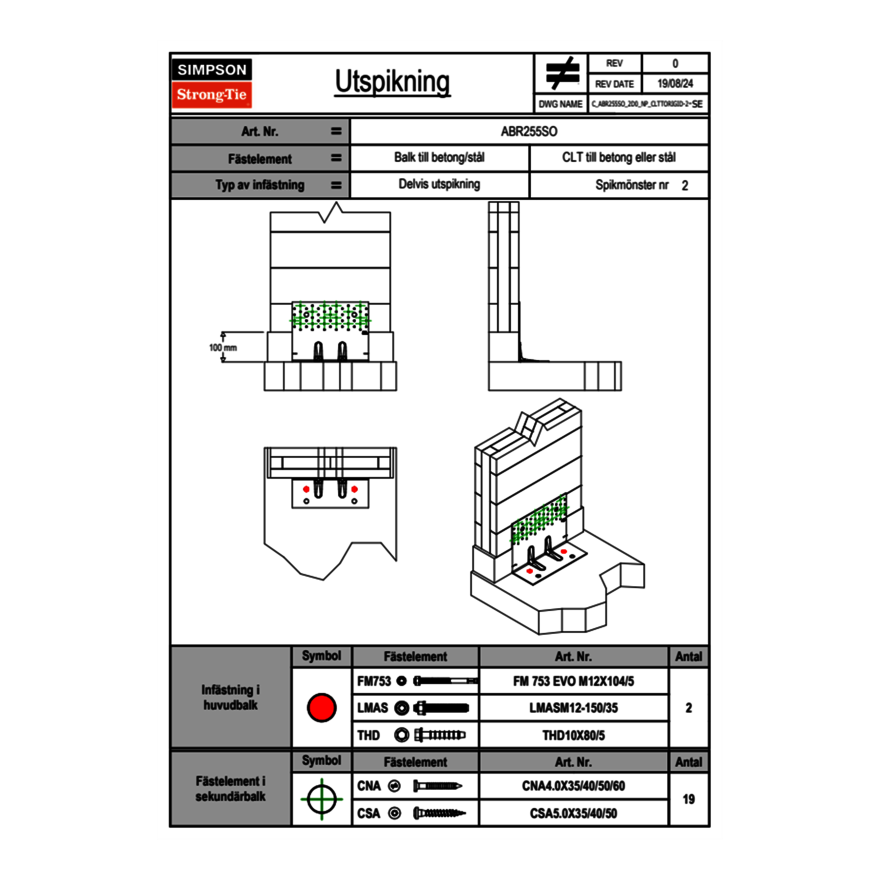

Karakteristisk bärförmåga - Balk på betong - 1 vinkelbeslag per fog - Delvis utspikning - Nailing pattern 2

| Art. nr. | Karakteristisk bärförmåga - Balk-betong fogningar - Delvis utspikning - Nailing pattern 2 | ||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Utspikning | Karakteristisk bärförmåga - 1 vinkelbeslag per fog [kN] | ||||||||||||||||||||

| Flik A | Flik B | R1.k | R2.k = R3.k | R4.k | R5.k | ||||||||||||||||

| - | Typ | - | Typ | CNA4.0x... | CNA4.0x... | CNA4.0x... | CNA4.0x... | ||||||||||||||

| 35 | 40 | 50 | 60 | 35 | 40 | 50 | 60 | 35-50-60 | 35 | 40 | 50 | 60 | 35 | 40 | 50 | 60 | |||||

| ABR255 | 30 | CNA | 2 | Ø12 | 15.94 | 18.8 | min (24,8 ; 22 / kmod) | min (30,3 ; 22 / kmod) | 21.6 | 23.7 | 29 | 32 | 18.3 / kmod^0,7 | 18.3/kmod^0,7 | 18.3/kmod^0,7 | 18.3/kmod^0,7 | 18.3/kmod^0,7 | 15.3/kmod^0.6 | 16.5/kmod^0.6 | min (19.9/kmod^0.4 ; 17.7 / kmod) | min (23.3/kmod^0.4 ; 17.7 / kmod) |

| ABR255SO | 19 | CNA | 2 | Ø12 | min (24,3; 22,9/kmod) | min (27,5; 22,9/kmod) | min (34,7; 22,9/kmod) | 22,9/kmod | 13.3 | 15.7 | 20.7 | - | 18,2 / kmod^0,66 | 18,2/kmod^0,66 | 18,2/kmod^0,66 | 18,2/kmod^0,66 | 18,2/kmod^0,66 | 5,05/kmod | 5,05/kmod | 5,05/kmod | 5,05/kmod |

Värdena gäller endast om elementen är förhindrade från att rotera.

-

| Art. nr. | - | |||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Utspikning | - [kN] | |||||||||||||||||||

| Flik A | Flik B | R1.k | R2.k = R3.k | R4.k | R5.k | |||||||||||||||

| - | Typ | - | Typ | CNA4.0x... | CNA4.0x... | CNA4.0x... | CNA4.0x... | |||||||||||||

| 35 | 40 | 50 | 60 | 35 | 40 | 50 | 60 | 35 | 40 | 50 | 60 | 35 | 40 | 50 | 60 | |||||

| ABR255 | 30 | CNA | 2 | Ø12 | 15.94 | 18.8 | 24.4 | 24.4 | 21.6 | 23.7 | 29.3 | 32 | 20.3 | 20.3 | 20.3 | 20.3 | 16.2 | 17.5 | 19.6 | 19.6 |

| ABR255SO | 19 | CNA | 2 | Ø12 | 20.8 | 20.8 | 20.8 | 2.08 | 13.3 | 15.7 | 20.7 | - | 17.1 | 17.1 | 17.1 | 17.1 | 4.6 | 4.6 | 4.6 | 4.6 |

The published characteristic capacity is based on short term load duration and service class 2 according to EC5 (EN 1995) – kmod = 0.9. For other load duration and service class, please refer to the ETA to get more accurate capacities.

The bolt design resistance requirement R#,d is determined from (bolt factor x connection design load F#,d) for the required load direction and fastener. Refer to the Simpson Strong-Tie anchor product range for suitable anchors. Typical anchor solutions are BOAXII, SET-XP, WA, AT-HP, depending on the concrete type, spacing and edge distances.

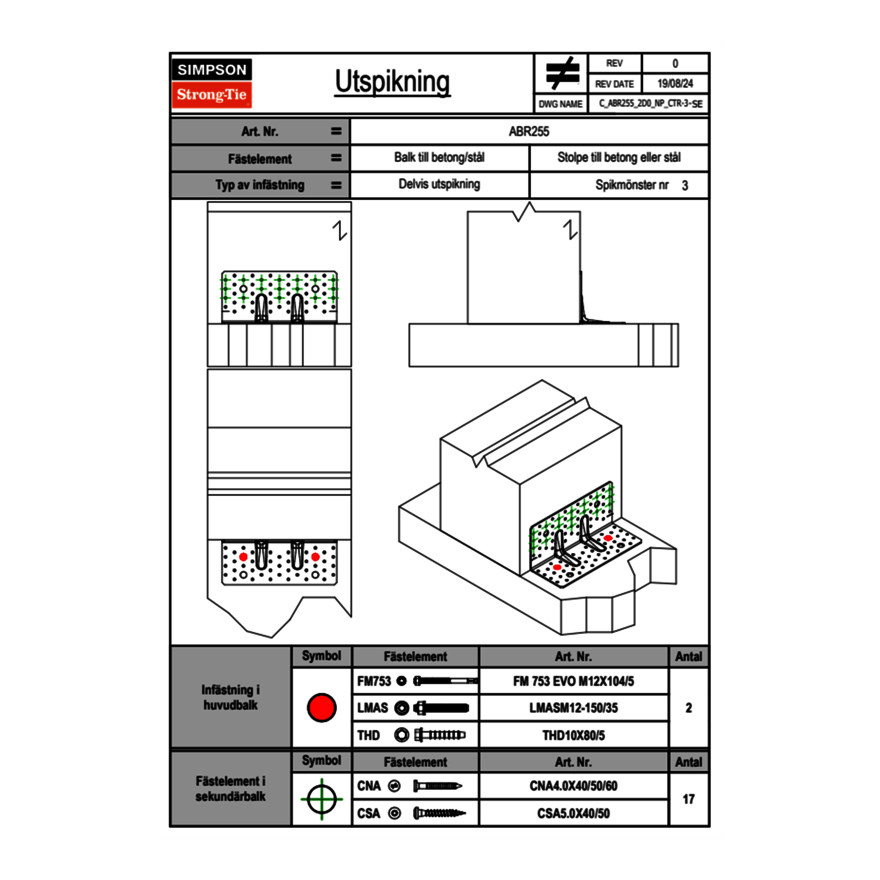

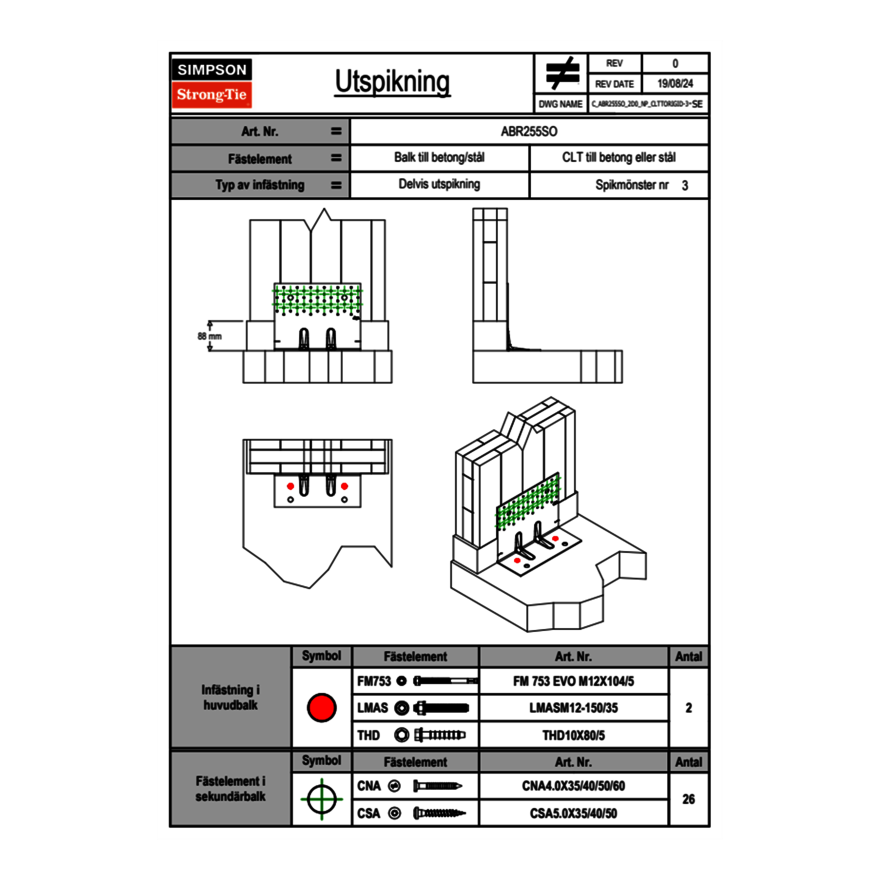

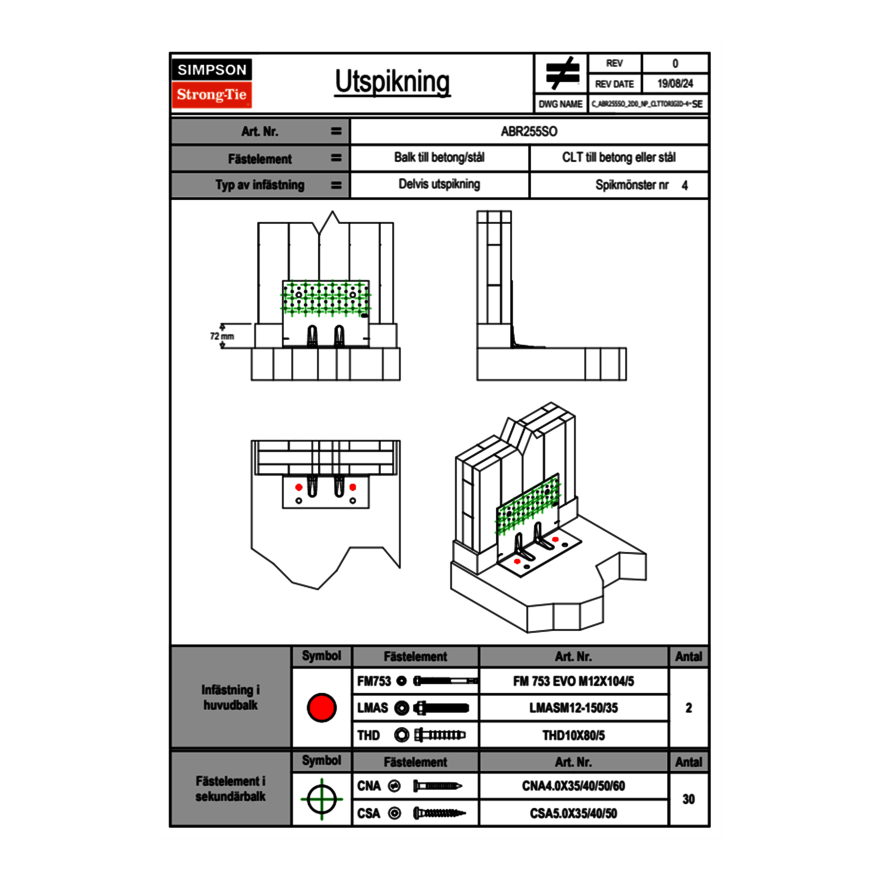

Karakteristik bärförmåga - Balk på betong - 1 vinkelbeslag per fog - delvis utspikning - nailing pattern 4

| Art. nr. | Karakteristisk bärförmåga - Trä-betong fogningar - Delvis utspikning - Nailing pattern 4 | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Utspikning | Characteristic capacities - Timber C24 - 1 angle bracket per connection [kN] | |||||||||||

| Flik A | Flik B | R1.k | R2.k = R3.k | R4.k | R5.k | |||||||

| Antal | Typ | Antal | Typ | CNA4.0x50 | CNA4.0x60 | CNA4.0x50 | CNA4.0x60 | CNA4.0x50 | CNA4.0x60 | CNA4.0x50 | CNA4.0x60 | |

| ABR255SO | 26 | CNA | 2 | Ø12 | 22,9/kmod | 22,9/kmod | 21.7 | - | 18,2/kmod^0,66 | 18,2/kmod^0,66 | 5,05/kmod | 5,05/kmod |

Värdet i tabellen ovan kan användas om panelen inte kan roteras.

Ankarkapaciteterna måste kontrolleras separat genom att multiplacera F1-belastningen med en faktor på 1.1, F2-belastningen med en faktor på 1 och F5 med en faktor på 2.2.

Spikmönster 4 har specifikt utvecklats för CLT-applikationer. Det kan användas för applikationer med andra träbaserade material, förutsatt att materialen uppfyller kraven för avstånd och placering av fästelement i CLT.

Förenklade karakteristiska kapaciteter – Trä till styvt underlag – 1 vinkelbeslag – Delvis spikning – Spikmönster 4

| Art. nr. | Förenklade produktkapaciteter – Trä mot betong – Delvis spikning – Spikmönster 4 | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Fasteners | Simplified characteristic capacities - Timber C24 - 1 angle bracket per connection [kN] | |||||||||||

| Flange A | Flange B | R1.k | R2.k = R3.k | R4.k | R5.k | |||||||

| Qty | Type | Qty | Type | CNA4.0x50 | CNA4.0x60 | CNA4.0x50 | CNA4.0x60 | CNA4.0x50 | CNA4.0x60 | CNA4.0x50 | CNA4.0x60 | |

| ABR255SO | 26 | CNA | 2 | Ø12 | 20.8 | 20.8 | 21.7 | - | 17.1 | 17.1 | 4.6 | 4.6 |

The published characteristic capacity is based on short term load duration and service class 2 according to EC5 (EN 1995) – kmod = 0.9. For other load duration and service class, please refer to the ETA to get more accurate capacities.

The bolt design resistance requirement R#,d is determined from (bolt factor x connection design load F#,d) for the required load direction and fastener. Refer to the Simpson Strong-Tie anchor product range for suitable anchors. Typical anchor solutions are BOAXII, SET-XP, WA, AT-HP, depending on the concrete type, spacing and edge distances.

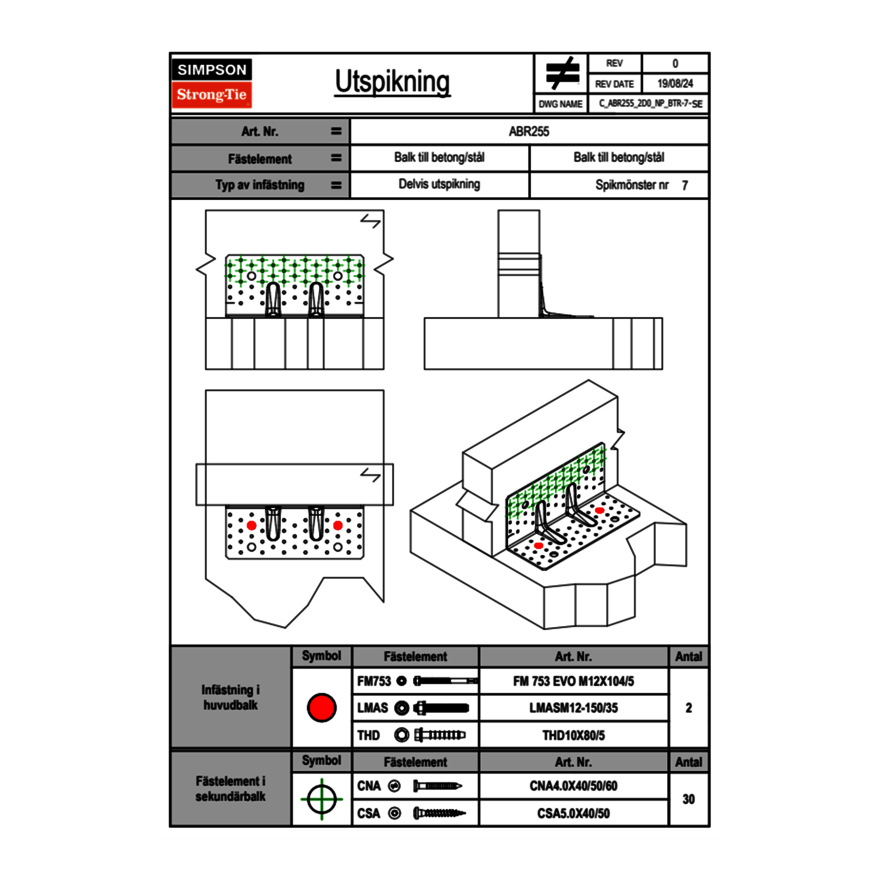

Karakteristisk bärförmåga - Balk på betong - 1 vinkelbeslag per fog - Delvis utspikning - Nailing pattern 7

| Art. nr. | Karakteristisk bärförmåga - Balk-betong fogningar - Delvis utspikning - Nailing pattern 7 | |||||||

|---|---|---|---|---|---|---|---|---|

| Utspikning | Karakteristisk bärförmåga - 1 vinkelbeslag per fog [kN] | |||||||

| Flik A | Flik B | R1.k | R2.k = R3.k | |||||

| - | Typ | - | Typ | CNA4.0x50 | CNA4.0x60 | CNA4.0x50 | CNA4.0x60 | |

| ABR255 | 30 | CNA | 2 | Ø12 | - | - | 39.8 | 42.5 |

| ABR255SO | - | - | - | - | - | - | - | - |

The value in the table above can be used if the panel can't rotate.

The anchor capacities must be checked separatly by multiplying the F2 load by a factor of 1.

Nailing pattern 7 has been specifically developed for CLT application. It can be used for applications with other timber based materials provided that the materials comply with the spacing and distances of fasteners in CLT.

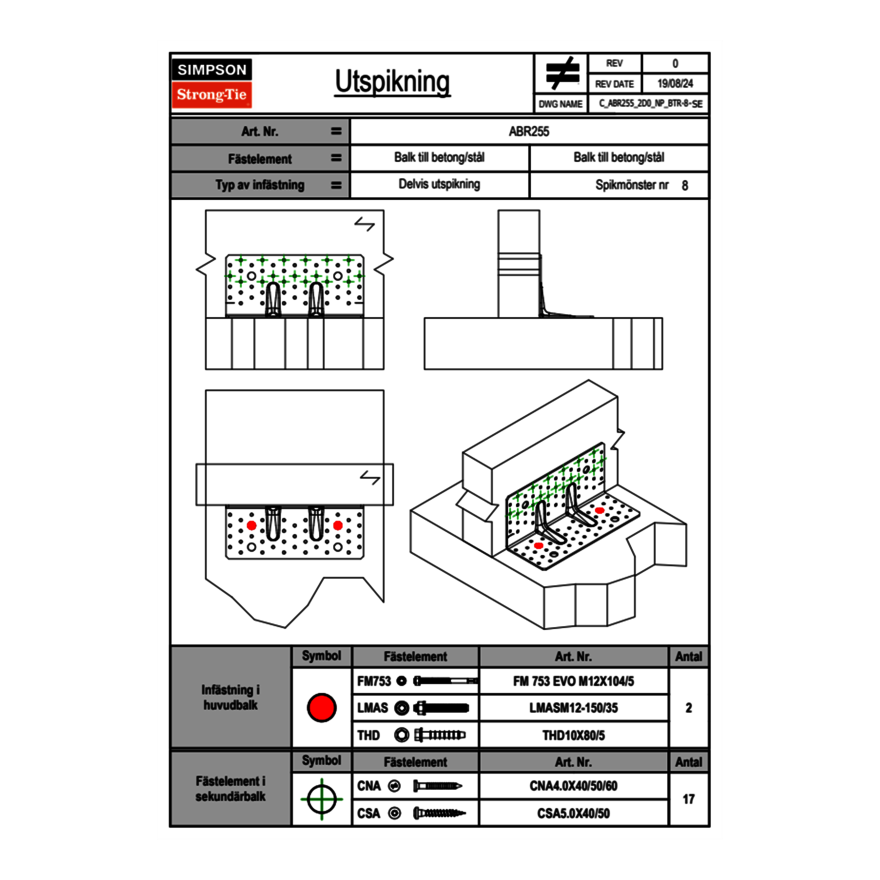

Karakteristisk bärförmåga - Balk på betong - 1 vinkelbeslag per fog - Delvis utspikning - Nailing pattern 8

| Art. nr. | Karakteristisk bärförmåga - Balk-betong fogningar - Delvis utspikning - Nailing pattern 8 | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Utspikning | Karakteristisk bärförmåga - 1 vinkelbeslag per fog [kN] | |||||||||||

| Flik A | Flik B | R1.k | R2.k = R3.k | R4.k | R5.k | |||||||

| - | Typ | - | Typ | CNA4.0x... | CNA4.0x... | CNA4.0x... | CNA4.0x... | |||||

| 50 | 60 | 50 | 60 | 50 | 60 | 50 | 60 | |||||

| ABR255 | 17 | CNA | 2 | Ø12 | 20 | 20 | 24.9 | 26.5 | 18.3/kmod^0.7 | 18.3/kmod^0.7 | 5.9/kmod^0.6 | 6.7/kmod^0.5 |

| ABR255SO | 30 | CNA | 2 | Ø12 | 22,9/kmod | 22,9/kmod | 26.1 | - | 18,2/kmod^0,66 | 18,2/kmod^0,66 | 5,05/kmod | 5,05/kmod |

The value in the table above can be used if the panel can't rotate.

The anchor capacities must be checked separatly by multiplying the F1 load by a factor 1.1, F2 load by a factor of 1 and F5 by a factor of 2.2.

Nailing pattern 8 has been specifically developed for CLT application. It can be used for applications with other timber based materials provided that the materials comply with the spacing and distances of fasteners in CLT.

Förenklade karakteristiska kapaciteter – Trä till styvt underlag – 1 vinkelbeslag – Delvis spikning – Spikmönster 8

| Art. nr. | Förenklade produktkapaciteter – Trä mot betong – Delvis spikning – Spikmönster 8 | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Fasteners | Simplified characteristic capacities - Timber C24 - 1 angle bracket per connection [kN] | |||||||||||

| Flange A | Flange B | R1.k | R2.k = R3.k | R4.k | R5.k | |||||||

| Qty | Type | Qty | Type | CNA4.0x50 | CNA4.0x60 | CNA4.0x50 | CNA4.0x60 | CNA4.0x50 | CNA4.0x60 | CNA4.0x50 | CNA4.0x60 | |

| ABR255 | 17 | CNA | 2 | Ø12 | 23.4 | 25.8 | 24.9 | 26.5 | 19.7 | 19.7 | 6.2 | 7 |

| ABR255SO | 56 | CNA | 2 | Ø12 | 20.8 | 20.8 | 26.1 | - | 17.1 | 17.1 | 4.6 | 4.6 |

The published characteristic capacity is based on short term load duration and service class 2 according to EC5 (EN 1995) – kmod = 0.9. For other load duration and service class, please refer to the ETA to get more accurate capacities.

The bolt design resistance requirement R#,d is determined from (bolt factor x connection design load F#,d) for the required load direction and fastener. Refer to the Simpson Strong-Tie anchor product range for suitable anchors. Typical anchor solutions are BOAXII, SET-XP, WA, AT-HP, depending on the concrete type, spacing and edge distances.

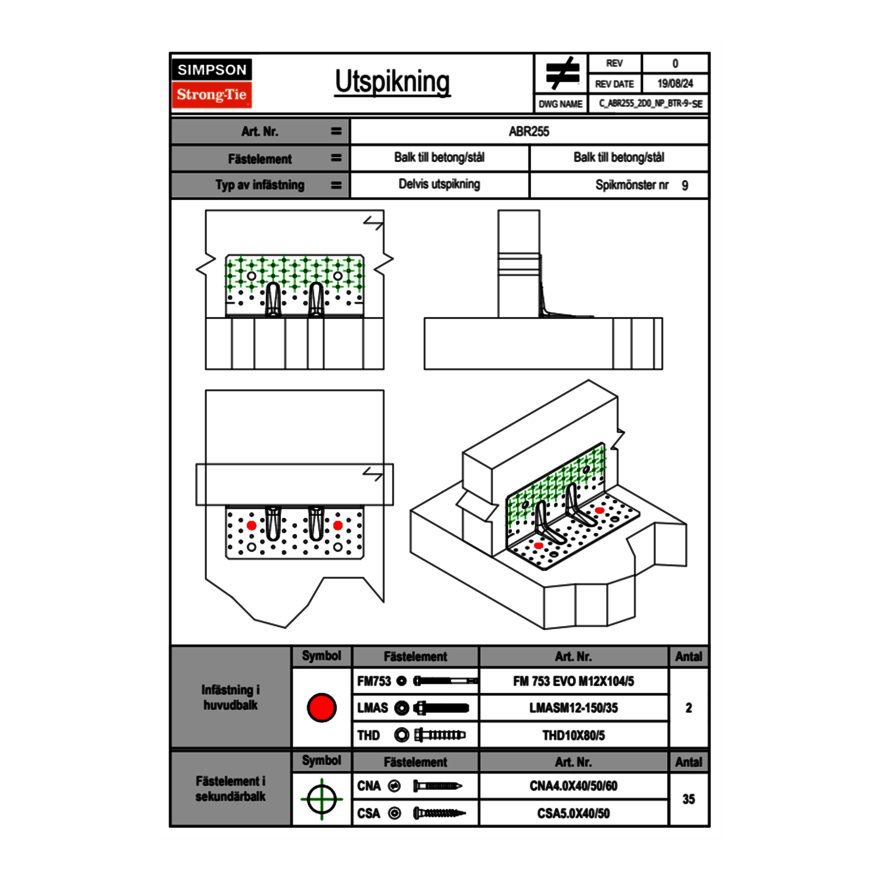

Karakteristisk bärförmåga - Balk på betong - 1 vinkelbeslag per fog - Delvis utspikning - Nailing pattern 9

| Art. nr. | Karakteristisk bärförmåga - Balk-betong fogningar - Delvis utspikning - Nailing pattern 9 | |||||

|---|---|---|---|---|---|---|

| Utspikning | Karakteristisk bärförmåga - 1 vinkelbeslag per fog [kN] | |||||

| Flik A | Flik B | R1.k | R2.k = R3.k | |||

| - | Typ | - | Typ | CSA 5,0x50 | CSA 5,0x50 | |

| ABR255 | 35 | CSA | 2 | Ø12 | min (79,5 ; 22 / kmod) | min (58 ; 57,6 / kmod) |

| ABR255SO | - | - | - | - | - | - |

The value in the table above can be used if the panel can't rotate.

The anchor capacities must be checked separatly by multiplying the F1 load by a factor 1.1 and F2 load by a factor of 1.

Nailing pattern 9 has been specifically developed for CLT application. It can be used for applications with other timber based materials provided that the materials comply with the spacing and distances of fasteners in CLT.