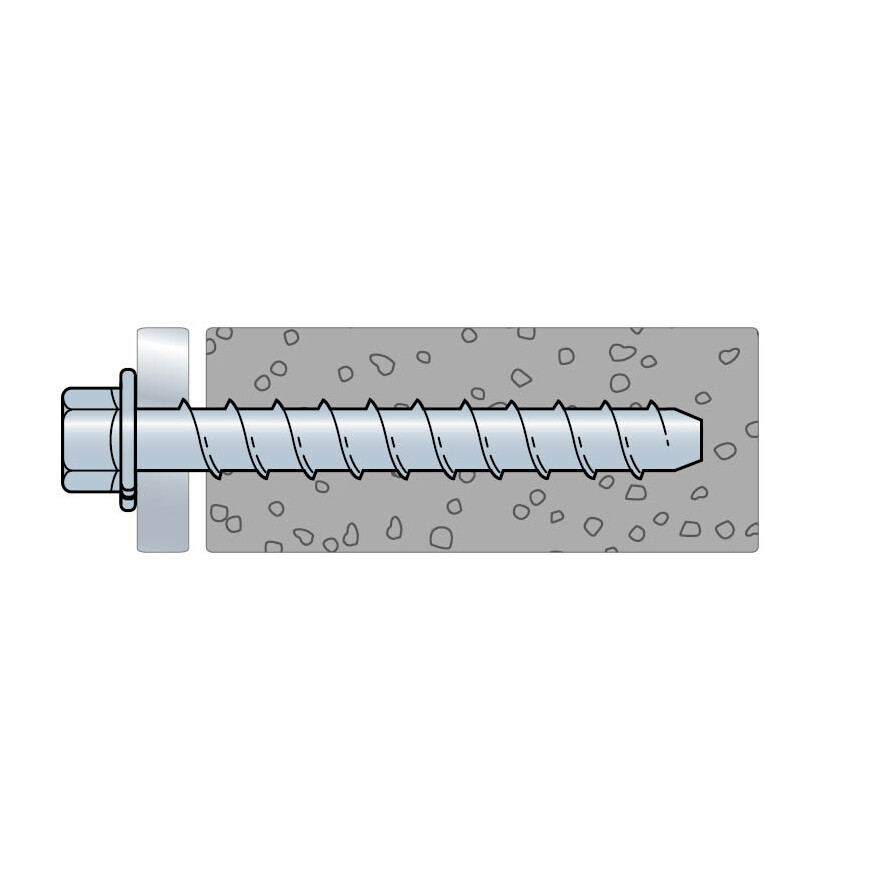

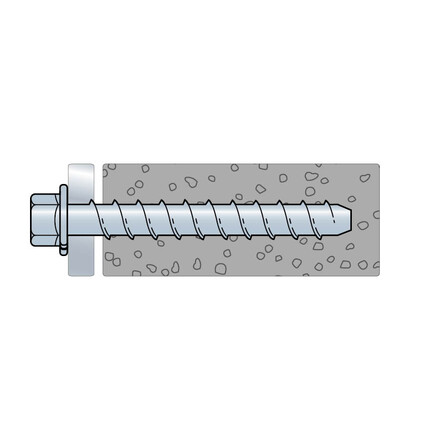

Betongskruv

Betongskruv för användning i både sprucken och osprucken betong. THD erbjuder lågt installationsmotstånd och enastående prestanda. THD är designad och utvecklad för torra, icke-korrosiva inomhusmiljöer.

Produktinformation

Egenskaper

Material

- Elektrogalvaniserat stål

Fördelar

- Optimerad gängdesign som effektivt överför lasten till underlaget

- Speciell värmebehandling för att öka hårdheten på spetsen och förenkla installationen

- Sexkanshuvud med underliggande bricka, kan installeras enkelt utan att addera en extra bricka

- Kan demonteras efter montage vid temporära konstruktioner som exempelvis avstyvning

Applikationer

Lämplig för

- Sprucken/osprucken betong samt lättklinkerbetong

Användningsområden

- Typisk användning:

Fästning av stålkonstruktioner, fasader, installationer, trappor, räcken, elementstöd, beslag

Teknisk data

Mått

| Art. nr. | Art. nr. |

Gäng- dimension [mm] [mm] | Totallängd [mm] | Max. materialtjocklek [mm] | Max. diameter af hål [mm] | Ø x djup i borrhål [mm] | Antal paket | Vikt [kg] |

|---|---|---|---|---|---|---|---|---|

| THD M8-70/5 | THD08070 | 10.3 | 70 | 5 | 12 | 8 x 75 | 50 | - |

| THD M8-80/15 | THD08080 | 10.3 | 80 | 15 | 12 | 8 x 75 | 50 | - |

| THD M8-120/55 | THD08120 | 10.3 | 120 | 55 | 12 | 8 x 75 | 50 | - |

| THD M10-80/5 | THD10080 | 12.5 | 80 | 5 | 14 | 10 x 85 | 50 | - |

| THD M10-100/25 | THD10100 | 12.5 | 100 | 25 | 14 | 10 x 85 | 50 | - |

| THD M10-120/45 | THD10120 | 12.5 | 120 | 45 | 14 | 10 x 85 | 50 | - |

| THD M10-170/95 | THD10170 | 12.5 | 170 | 95 | 14 | 10 x 85 | 50 | 0.12 |

Design Resistance

| Art. nr. | Konstruktionsmotstånd | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Spänning - NRd [kN] | Skjuvning - VRd [kN] | Böjmoment– MRd [Nm] | |||||||||||||||

| Sprickbildad betong | Icke-sprickbildad betong | Cracked concrete | Non-cracked concrete | ||||||||||||||

| C20/25 | C30/37 | C40/50 | C50/60 | C20/25 | C30/37 | C40/50 | C50/60 | C20/25 | C30/37 | C40/50 | C50/60 | C20/25 | C30/37 | C40/50 | C50/60 | ||

| THD M8-70/5 | 3.3 | 4.1 | 4.7 | 5.2 | 4.2 | 5.1 | 5.9 | 6.5 | 11.7 | 11.7 | 11.7 | 11.7 | 11.7 | 11.7 | 11.7 | 11.7 | 26.7 |

| THD M8-80/15 | 3.3 | 4.1 | 4.7 | 5.2 | 4.2 | 5.1 | 5.9 | 6.5 | 11.7 | 11.7 | 11.7 | 11.7 | 11.7 | 11.7 | 11.7 | 11.7 | 26.7 |

| THD M8-120/55 | 3.3 | 4.1 | 4.7 | 5.2 | 4.2 | 5.1 | 5.9 | 6.5 | 11.7 | 11.7 | 11.7 | 11.7 | 11.7 | 11.7 | 11.7 | 11.7 | 26.7 |

| THD M10-80/5 | 4.2 | 5.1 | 5.9 | 6.5 | 5.8 | 7.1 | 8.2 | 9 | 18.3 | 18.3 | 18.3 | 18.3 | 18.3 | 18.3 | 18.3 | 18.3 | 52.7 |

| THD M10-100/25 | 4.2 | 5.1 | 5.9 | 6.5 | 5.8 | 7.1 | 8.2 | 9 | 18.3 | 18.3 | 18.3 | 18.3 | 18.3 | 18.3 | 18.3 | 18.3 | 52.7 |

| THD M10-120/45 | 4.2 | 5.1 | 5.9 | 6.5 | 5.8 | 7.1 | 8.2 | 9 | 18.3 | 18.3 | 18.3 | 18.3 | 18.3 | 18.3 | 18.3 | 18.3 | 52.7 |

| THD M10-170/95 | 4.2 | 5.1 | 5.9 | 6.5 | 5.8 | 7.1 | 8.2 | 9 | 18.3 | 18.3 | 18.3 | 18.3 | 18.3 | 18.3 | 18.3 | 18.3 | 52.7 |

1) The design resistances have been calculated using the partial safety factors for resistances stated in ETA-12/0060.

2) The recommended loads have been calculated using the partial safety factors for resistances stated in ETA-12/0060 and with a partial safety factor for actions of

γF=1.4.

3) The load figures are valid for unreinforced concrete and reinforced concrete with a rebar spacing s ≥ 15 cm (any diameter) or with a rebar spacing s ≥ 10 cm, if

the rebar diameter is 10 mm or smaller.

4) “For combined tension and shear loads or anchor groups and/or in case of edge influence, a calculation per ETAG 001, Annex C, design method A or according to

CEN/TS 1992-4:2009 design method A shall be performed. Anchors under fire exposures are to be designed in accordance with EOTA -TR 020:2004 or CEN/TS 1992-4:2009 Annex D.

For details see ETA-12/0060.

Recommended loads - cracked concrete

| Art. nr. | Draghållfasthet (1-2) [Rds,N] [kN] | Skjuvhållfasthet (1-3) [Rds,V] [kN] | Böjmoment(1-6) [Mrds] [Nm] | ||||||

|---|---|---|---|---|---|---|---|---|---|

| C20/25 | C30/37 | C40/50 | C50/60 | C20/25 | C30/37 | C40/50 | C50/60 | sprucken betong C20/25 | |

| THD M8-70/5 | 2.4 | 2.9 | 3.4 | 3.7 | 8.3 | 8.3 | 8.3 | 8.3 | 19 |

| THD M8-80/15 | 2.4 | 2.9 | 3.4 | 3.7 | 8.3 | 8.3 | 8.3 | 8.3 | 19 |

| THD M8-120/55 | 2.4 | 2.9 | 3.4 | 3.7 | 8.3 | 8.3 | 8.3 | 8.3 | 19 |

| THD M10-80/5 | 3 | 3.6 | 4.2 | 4.6 | 13 | 13 | 13 | 13 | 37.6 |

| THD M10-100/25 | 3 | 3.6 | 4.2 | 4.6 | 13 | 13 | 13 | 13 | 37.6 |

| THD M10-120/45 | 3 | 3.6 | 4.2 | 4.6 | 13 | 13 | 13 | 13 | 37.6 |

| THD M10-170/95 | 3 | 3.6 | 4.2 | 4.6 | 13 | 13 | 13 | 13 | 37.6 |

Servicekostnader – obrutet betong

| Art. nr. | Draghållfasthet (1-2) [Rds,N] [kN] | Skjuvhållfasthet (1-3) [Rds,V] [kN] | ||||||

|---|---|---|---|---|---|---|---|---|

| C20/25 | C30/37 | C40/50 | C50/60 | C20/25 | C30/37 | C40/50 | C50/60 | |

| THD M8-70/5 | 3 | 3.6 | 4.2 | 4.6 | 8.3 | 8.3 | 8.3 | 8.3 |

| THD M8-80/15 | 3 | 3.6 | 4.2 | 4.6 | 8.3 | 8.3 | 8.3 | 8.3 |

| THD M8-120/55 | 3 | 3.6 | 4.2 | 4.6 | 8.3 | 8.3 | 8.3 | 8.3 |

| THD M10-80/5 | 4.2 | 5.1 | 5.9 | 6.5 | 13 | 13 | 13 | 13 |

| THD M10-100/25 | 4.2 | 5.1 | 5.9 | 6.5 | 13 | 13 | 13 | 13 |

| THD M10-120/45 | 4.2 | 5.1 | 5.9 | 6.5 | 13 | 13 | 13 | 13 |

| THD M10-170/95 | 4.2 | 5.1 | 5.9 | 6.5 | 13 | 13 | 13 | 13 |

1) The recommended loads have been calculated using the characteristic capacities stated in the ETA with the partail safety factors given in the ETAG001 and the partial safety factor for loads: f = 1.4.

2) The recommended axial loads are valid for unreinforced concrete and reinforced concrete with a rebar spacing s ≥ 15 cm (any diameter) or with a rebar spacing s ≥ 10 cm, if the rebar diameter is 10 mm or smaller.

3) The figures for shear are based on a single anchor without influence of concrete edges. For anchorages close to edges (c ≤ max [10 hef; 60d]) the concrete edge failure shall be checked per

ETAG 001, Annex C, design method A.

4) Concrete is considered non-cracked when the tensile stress within the concrete is \sigmaL + \sigmaR ≤ 0. In the absence of detailed verification \sigmaR = 3 N/mm² can be assumed ( \sigmaL equals the tensile

stress within the concrete induced by external loads, anchors loads included).

5) If spacings or edge distances are lower than characteristic ones (S ≤ Scr,N and/or C ≤ Ccr,N ) then the calculation should be made according to ETAG001, annex Cn A method. For further information see ETA-06/0123

6) The recommended bending moment is only valid for threaded rods.

Tillåtna belastningar

| Art. nr. | tillåtna belastningar i C20/25 **) | |

|---|---|---|

| Nzul [kN] | Vzul [kN] | |

| THD M8-70/5 | 2.4 | 8.3 |

| THD M8-80/15 | 2.4 | 8.3 |

| THD M8-120/55 | 2.4 | 8.3 |

| THD M10-80/5 | 3 | 13 |

| THD M10-100/25 | 3 | 13 |

| THD M10-120/45 | 3 | 13 |

| THD M10-170/95 | 3 | 13 |

**) Permissible loads apply to single anchors in cracked concrete without the influence of center and edge distances

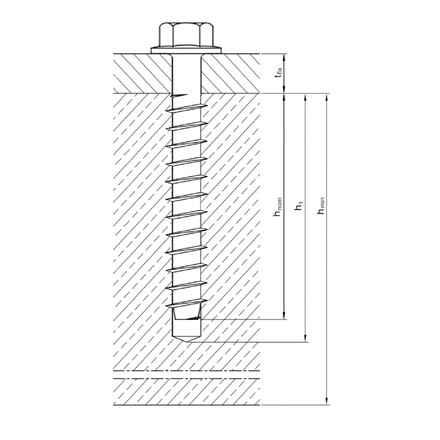

Montage

Montage

Installation

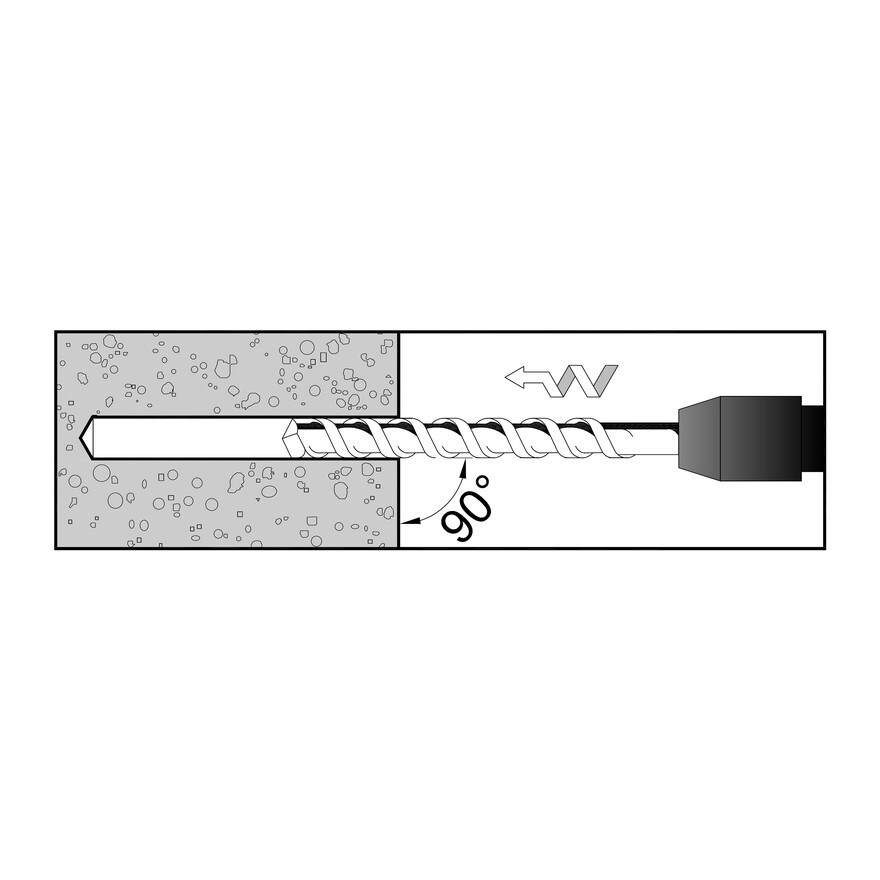

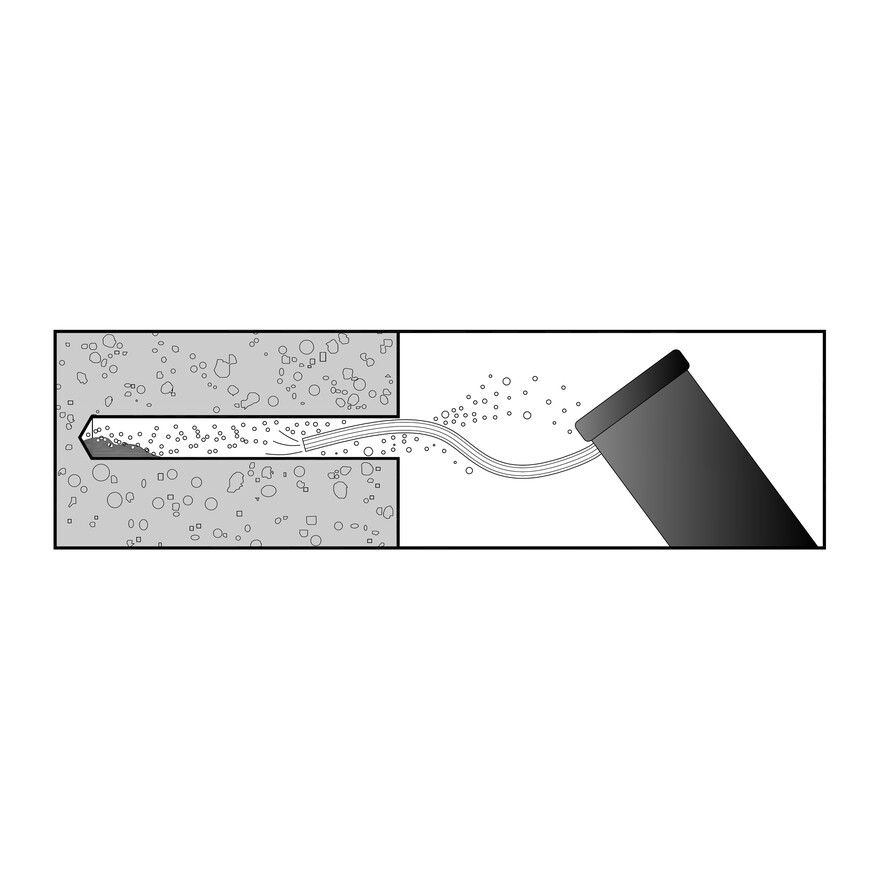

- Borra ett hål i underlaget med en hårdmetallborr med samma diameter som den nominella diametern på det förankringselement som ska installeras. Borra hålet till angivet infästningsdjup plus minsta totala håldjup (se tabell nedan till höger) så att gängspån kan sedimentera, och blåsa rent med tryckluft. (Överliggande installationer behöver inte blåsas rena.) Alternativt kan hålet borras tillräckligt djupt för att rymma infästningsdjupet och borr- och gängspån.

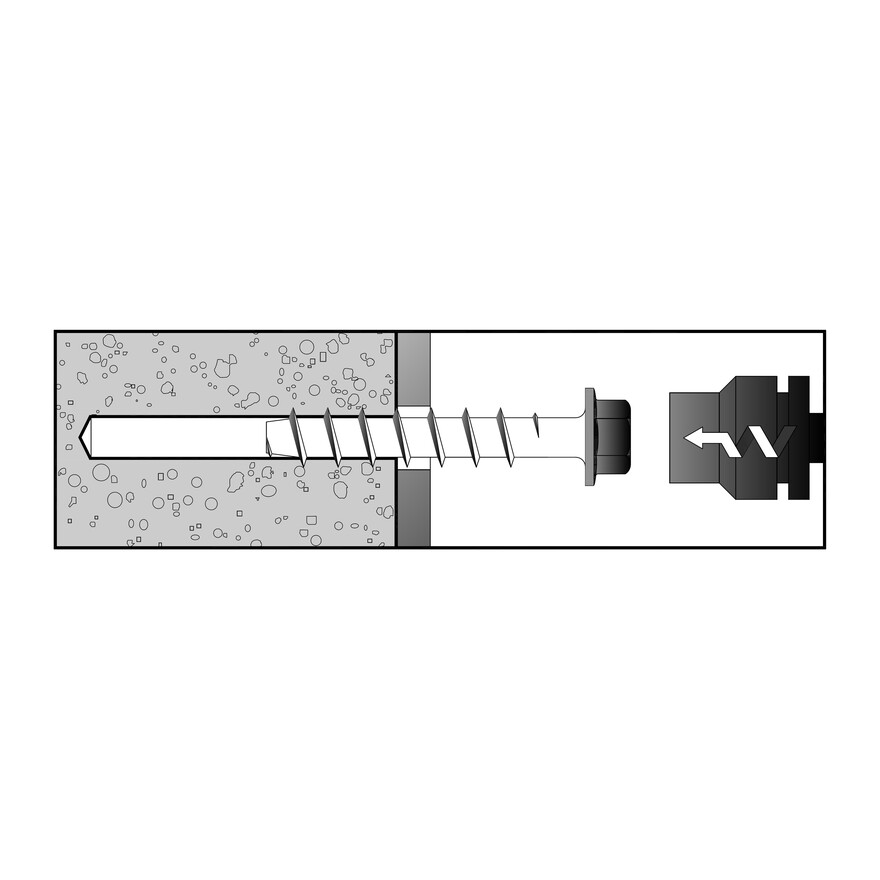

- För in ankaret genom fästet och in i hålet.

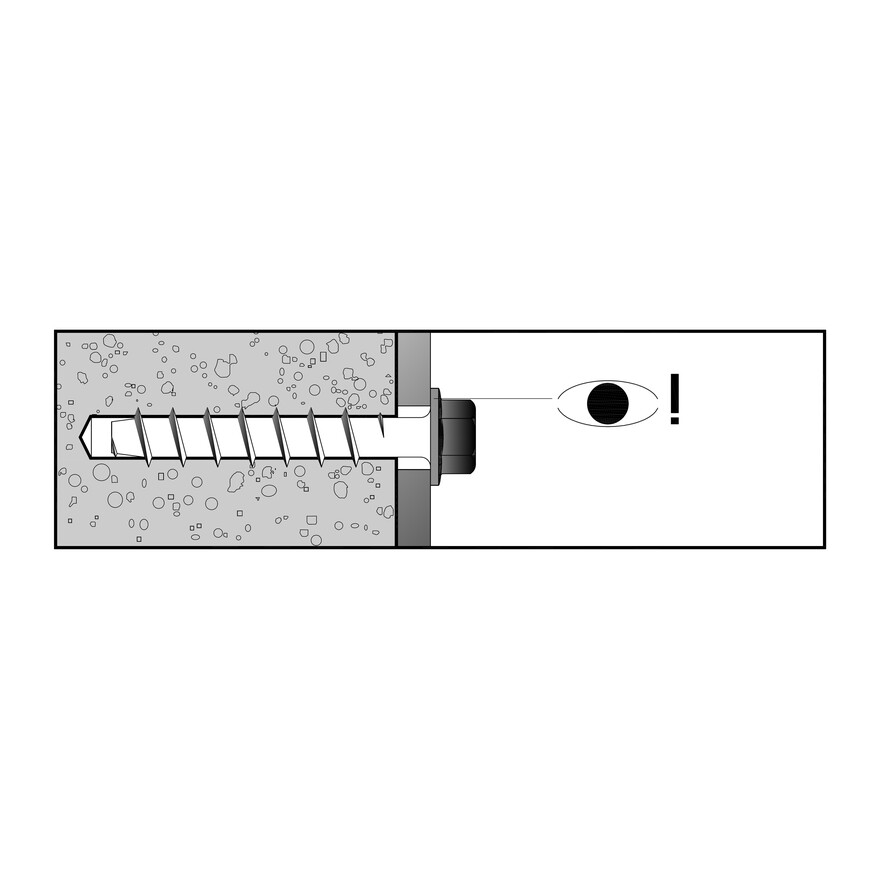

- Dra åt ankaret i basmaterialet tills sexkantsbrickan kommer i kontakt med fixturen.

Montering

| Art. nr. | Borrdiameter [mm] | Min. drill depth - h1 [mm] | Ø gennemfaldshål [mm] | Skiftnyckel storlek | Installationsmomentet [Nm] | Impact screw driver (7) - Tsd [Nm] | Sättdjup [mm] | Rekommenderade avståndet(5) - Scr,N [mm] | Min. avstånd mellan verandre [mm] | Karakteristisk kantavstånd [mm] | Min. kantavstånd [mm] | Min. support thickness - hmin [mm] |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| THD M8-70/5 | 8 | 75 | 12 | 13 | NA | ≤ 200 | 47 | 141 | 50 | 70.5 | 50 | 105 |

| THD M8-80/15 | 8 | 75 | 12 | 13 | NA | ≤ 200 | 47 | 141 | 50 | 70.5 | 50 | 105 |

| THD M8-120/55 | 8 | 75 | 12 | 13 | NA | ≤ 200 | 47 | 141 | 50 | 70.5 | 50 | 105 |

| THD M10-80/5 | 10 | 85 | 14 | 15 | 75 | ≤ 515 | 55 | 165 | 60 | 82.5 | 60 | 125 |

| THD M10-100/25 | 10 | 85 | 14 | 15 | 75 | ≤ 515 | 55 | 165 | 60 | 82.5 | 60 | 125 |

| THD M10-120/45 | 10 | 85 | 14 | 15 | 75 | ≤ 515 | 55 | 165 | 60 | 82.5 | 60 | 125 |

| THD M10-170/95 | 10 | 85 | 14 | 15 | 75 | ≤ 515 | 55 | 165 | 60 | 82.5 | 60 | 125 |